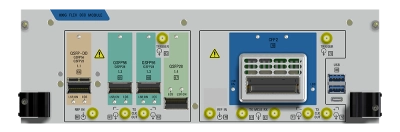

The VIAVI 800G FLEX DCO Module provides a wide range of critical test and measurement capabilities that manufacturers need to design and validate pluggable digital coherent optical modules. Native support for both 400G class CFP2 (DCO) and QSFP-DD 400ZR modules is backed by a solid power and thermal cooling environment. Electrical adapters allow testing on prototype boards and ICs before module integration, greatly accelerating product development.

The complementary VIAVI MAP-300 optical products provide photonic solutions for R&D, SVT, and production to deliver the industry’s only complete photonics and protocol one-stop solution for R&D and production test for coherent modules.

Benefits

- Ensures eco-system interoperability

- Enables reliable performance

- Accelerates test times and coverage to meet aggressive volume and cost expectations

Key Features

- Support for native 400G Pluggable Coherent Modules via CFP2-DCO and QSFP-DD 400ZR with substantial cooling margin up to 32 W

- QSFP-DD and QSFP56 Electrical Adapter

- Ethernet 400GE and 200GE

- Ethernet breakout 8x50GE, 2x200GE, 4x100GE

- Ethernet breakout 2x100GE, 1x200GE NRZ

- OTN FlexO FOIC and OTLCn up to OTUC4

- FlexE with 100G, 200G and 400G PHY

- Dynamic Skew

- Advanced Error Anaylsis

- FEC Error Insertion and RX Statistics

- FEC Stress Testing for PAM-4 coded signals

- OTN Multiplexing and Ethernet Client Service Mapping

- Multi-user support and independent test ports

- Test Automation

Literatura

Data sheets

Artigos técnicos e livros

Downloads e atualizações de software

Care Support Plans

| Product Group | Recommended Plan | Bronze | Silver | Maxcare | |

|---|---|---|---|---|---|

| ONT (Mainframe/ Module) | Bronze-3 | Does the product require calibration? Common questions or issues |

-

VIAVI Care Support

Services Bronze Silver MaxCare Imagem Imagem

Imagem Imagem

Imagem

Technical Assistance Premium Premium Premium Factory Repair Priority Service Self-paced Training Factory Calibration Express Loaner * 5-year plans only; if applicable

-

VIAVI Care Support for Existing Equipment

FleetCare plans can be customized to include any service entitlements on your fleet of existing equipment. Please fill out a Service Contracts form for a quote.

- Any collection instruments with a single coterminous renewal date

- Each contract is customized with any number of annual terms required by the customer

- Onsite Calibration, Training, Field Application Engineer days can be added

Assistência em cada passo

Oferecemos assistência, serviços, treinamento completo e os recursos de que você precisar. Isso tudo faz parte do que fazemos para maximizar o valor de seu investimento VIAVI.

Queremos ajudar

Estamos aqui para ajudar no seu futuro.