5G Installation

5G Installation Install and Test 5G Networks with Versatile and Automated Solutions

5G installation is driving advances and upgrades that span the entire wireless network ecosystem. The stringent test requirements and unique installation challenges for new 5G cell sites and RAN deployments can only be addressed through versatile, automated 5G test solutions. VIAVI has developed an industry-leading 5G test suite encompassing RF, fiber, antenna, radio access, and system test solutions that accelerate the evolution of 5G.

What is 5G Installation?

5G network installation includes the setup, deployment, and verification of new radios, antennas, fiber links, and power sources. The next-generation of radio access networks (RAN) also brings wholesale changes to fronthaul, mid-haul, and backhaul fiber installation to support split BBU architecture and network function virtualization (NFV).

The time and resources required to install a 5G network have led to a measured transition from legacy wireless network technology. Non-standalone (NSA) mode allows a 5G radio network to utilize an LTE Core. The addition of new 5G radios and antennas to existing cell sites compresses deployment timelines. Despite these efficiencies, the pace of 5G installation continues to be gated by site, equipment, and technician availability.

Installing a 5G Network

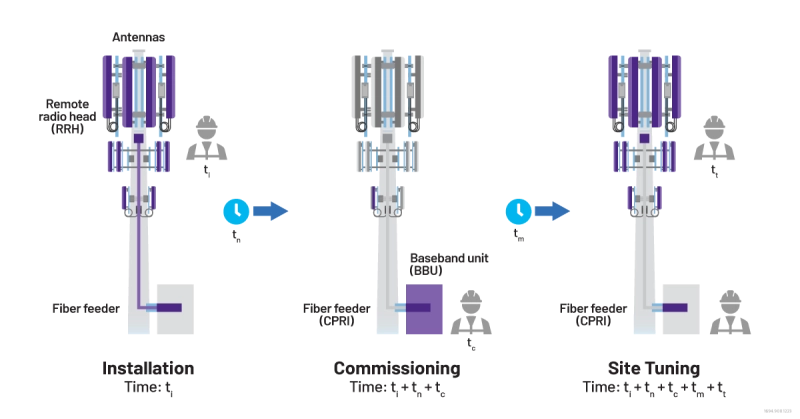

5G network installation involves months of planning and preparation even before the first radio or antenna is connected. This is especially true for ground-up 5G mobile tower installation with complex construction tasks layered upon 5G hardware and fiber installation and commissioning.

- Fiber installation is complicated by 5G Massive MIMO (multiple input, multiple output) antenna technology used to focus energy and increase data rates through spatial multiplexing. Increased fiber counts magnify the importance of good fiber hygiene practices. Repeat tower climbs and troubleshooting can be minimized for 5G installation technicians through automated, handheld, fiber and connector inspection tools designed for multi-fiber connectivity.

- 5G antenna installation tasks are transformed by millimeter wave transmission. Higher frequencies and shorter wavelengths result in smaller antenna form factors with high connection density. 5G antenna integrators at the top of the tower perform valuable antenna alignment tasks to ensure optimized coverage and service. Sites where coax is still used to connect antennas benefit from cable sweep testing to verify connection integrity.

- New 5G test innovations reduce the impact of 5G RAN complexity on cell site installation and commissioning timelines. Baseband unit emulation can be used to simulate BBU transmission to the remote radio unit (RRU) prior to actual BBU installation and commissioning. This allows the radio head configuration, link status, signal quality, and antenna tilt to be verified early, while a 5G installation technician is still available for adjustments or repairs.

5G Tower Installation

Massive cell towers dotting the landscape are the product of intense site preparation and tons of steel and poured concrete. Heavy equipment used to hoist tower segments hundreds of feet into the air signals the beginning of extensive infrastructure integration and testing. 5G tower installation has become more diversified, with small cells and femtocells complimenting the familiar, sky high macro-cell towers.

- Repurposing of existing cell towers is an important element of the 5G tower installation strategy. With previous generation hardware still in place, this approach places a premium on compact, lightweight remote radio head (RRH) and antenna components that are easy for 5g installation technicians to carry and install.

- Fiber to the antenna (FTTA) installation must accommodate 5G multi-fiber connections replacing single fiber pairs. With the millimeter wave, ultra-reliable low latency communication (uRLLC), and increased densification rewriting the rules for how to install 5G network components, repurposing of existing infrastructure is just one piece of the 5G installation puzzle.

- Small cells with low power consumption leverage their compact size and ease of installation to compensate for the limited range and high penetration loss of millimeter wave transmission. Installing small cells for 5G can take just hours, rather than months or years. Thorough coverage mapping of a small cell deployment is recommended to safeguard performance for indoor or outdoor settings.

5G Installation Challenges

With the pressure building to quickly install new 5G network infrastructure, operators and 5G tower installation companies face challenges that are unique to next generation wireless. A combination of advanced test tools, automation, and training can accelerate 5G installation while improving long term reliability.

- Fiber Density

Dirty or contaminated fiber end faces and connectors are common causes of signal impairment. A particle as small as 1 micron in size can cause an installation failure. Loose connections and “rolled” fiber (polarity) errors can lead to similar issues. These challenges are intensified by windy outdoor conditions and the high fiber volume required to support 5G antennas and fronthaul. - Massive MIMO

As a centerpiece of 5G installation, Massive MIMO technology brings benefits in coverage and capacity along with new installation challenges. Steerable antennas and beamforming techniques improve throughput and efficiency, but require a high level of precision for alignment, synchronization, and OTA testing. Urban installations with more antenna obstructions highlight the need for automated line of site (LOS) surveying and validation. - 5G Tower Installation Companies

The largest U.S. cell tower operators now control tens of thousands of towers, with 5G customers eagerly anticipating new deployments. Securing new locations can be complicated by zoning and environmental concerns as 5G towers become more conspicuous. The unprecedented demand for 5G infrastructure has spurred new FCC legislation intended to speed up installation by easing regulations. - 5G Installation Resources

An ongoing shortage of skilled labor has put the experienced 5G installation technician in high demand. New technologies, challenging work conditions, and cell site densification have contributed to technician shortages that can delay installation timelines. Automated 5G test solutions lessen the impact by reducing training time, standardizing workflows, and consolidating test capabilities within rugged, compact, and cloud-enabled tools.

5G Network Maintenance and Optimization

Once installation of the 5G network is complete, network performance and QoS is assured through ongoing monitoring and maintenance. Efficient, easy-to-use test solutions support proactive 5G network maintenance and reduce OPEX by identifying issues quickly and consistently.

- Fiber Troubleshooting

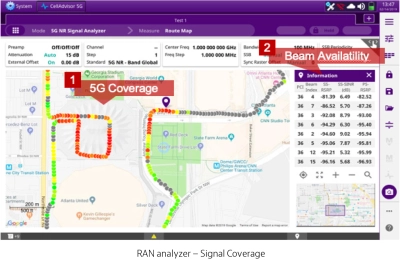

Even properly cleaned and inspected fiber links are subject to macro bends, pinching, or connector failures over time. An OTDR module configured for the specific fiber application (xWDM, PON, etc.) is an ideal tool for monitoring end-to-end optical return loss (ORL) or quickly diagnosing the source and location of any fiber link issues. - Spectrum Analysis

After installing a 5G cell site, live network troubleshooting often requires advanced spectrum and interference analysis capabilities. Real-time spectrum analysis is essential for characterizing 5G C-band and millimeter wave transmissions utilizing time division duplex (TDD) communication. Interference profiles can change quickly as new 5G radio transmitters and unintentional emission sources are introduced. - Test Processes Automation

Technical resource constraints can extend beyond the 5G installation technician. Overloaded equipment manufacturers, service providers, and maintenance contractors also benefit from the improved efficiency delivered by consistent, repeatable test process automation (TPA). Manual test processes and data entry are reduced as installation and maintenance workflows are executed and reported automatically. Network monitoring and assurance solutions also leverage machine learning (ML) algorithms to predict future issues.

Tools for 5G Installation

VIAVI provides a comprehensive test suite to confidently address all aspects of 5G cell site installation and commissioning. The advanced TPA features offered on all VIAVI instruments streamline workflows and minimize guesswork and training.

- OneAdvisor 800

The OneAdvisor 800 is an all-in-one 5G network installation, maintenance, and troubleshooting solution that combines advanced OTDR, fiber scope, spectrum analysis, and antenna alignment capabilities in one compact and intuitive instrument. Pre-configured workflows, built-in user guidance, and small cell compatibility make the OneAdvisor 800 a 5G installation tool of choice.- Cable and Antenna Analyzer (CAA) Module

The optional CAA module for OneAdvisor 800 intuitively guides the 5G installation technician through a sweep testing process that characterizes feed lines, verifies system integration, and confirms antenna performance.

- Cable and Antenna Analyzer (CAA) Module

- P5000i and FiberCheck Probe

Fiber microscopes seamlessly integrate with VIAVI test solutions to provide fully automated PASS/FAIL fiber end face inspection and certification. Advanced auto-focus, storage, and recall features support the breadth of new fiber link configurations for 5G mobile tower installation. - RF Vision

5G antenna installation requires innovative alignment tools to ensure correct positioning and no obstructions. RF Vision uses an integrated camera, dual-frequency technology, and a user-friendly GUI to accurately align directional antennas, generate automated line-of-site surveys, and match antenna alignment profiles with RF design. Augmented reality is used to enhance bullseye target alignment. - StrataSync

With test process automation at the core of the VIAVI 5G installation philosophy, the StrataSync™ test process automation suite provides an ideal hub for deploying test procedures, automating workflows, and managing assets and data. StrataSync JobManager for OneAdvisor 800 streamlines the test process, allowing technicians to install 5G network infrastructure with consistent, safe, and efficient workflows.