FV microscopes equip optical connectivity manufacturers and users with the ability to ensure clean fiber connector end-faces by detecting contamination and defects that are present. Both manufacturers and users of optical connectivity can leverage the benefits of the FV microscopes to ensure end-face cleanliness and quality.

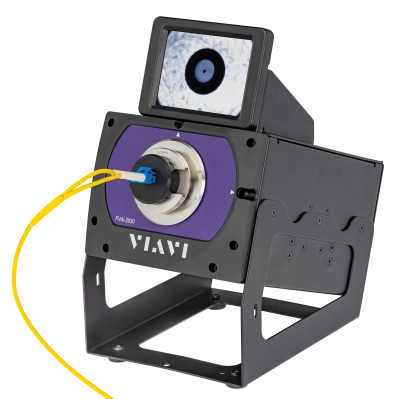

Available in two magnification configurations, 30x (2030) and 400x (2400), FV microscopes give operators the ability to leverage the benefits of each. The 2030 microscope is ideal for confirming connector cleanliness throughout manufacturing process while the 2400 microscope is targeted for high resolution applications including confirming polish quality and certifying connector quality

Benefits

- Easily detect contamination and defects on fiber connector end-faces

- Control end face contamination throughout the entire manufacturing process with the right tool at each stage

- Improve production yields by eliminating costly component damage

- Leverage manufacturing efficiencies by automating various procedures

- Save valuable benchtop space with compact size

- Certify product quality and maintain digital records

Applications

- Post-polish certification to IEC

- Identify contamination during the various stages of manufacturing and test (polarity test, IL/RL and final inspection)

- Identify contamination during mechanical (connector body, cassette, cabinet, pedestal) assembly

- Final packaging verification to IEC certification

Descargas y actualizaciones de software

Literatura

Hojas de especificaciones

Guía de selección

Versiones de software y firmware

Documentos técnicos y bibliografía

Descargas y actualizaciones de software

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards

Productos Relacionados

Asistencia en cada paso

Proporcionamos soporte técnico, servicios, una formación completa y los recursos que necesita. Todo ello forma parte de lo que hacemos con el fin de maximizar el valor de su inversión en VIAVI.

Déjenos ayudarle

Estamos a su disposición para ayudarle a avanzar.