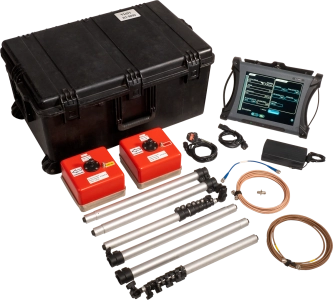

The ALT-8000 is the world's first and only RF-based portable radio altimeter flight line test set. It weighs approximately 10 lbs. (4.5 kg) with a large 12-inch color touch-screen, making it easy to use. The ALT-8000 is a universal test set for 4.3 GHz FMCW (frequency modulated continuous carrier wave) radio altimeters and pulse radio altimeters. The simulator is also designed to be software upgradable. For military applications, see the ALT-8015

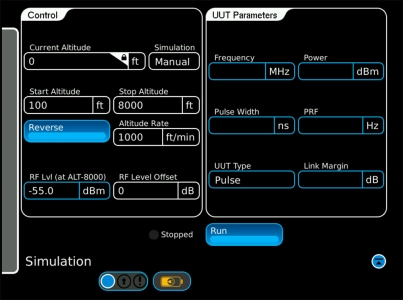

General - The user interface is Windows® based and provides various pages for control of the test set and display of parametric measurements including: TX power, TX frequency (center), sweep rate, TX pulse width (pulse systems).

Profiles - The Profile page allows the user to create, save, recall or delete named profiles. Each profile is comprised of individual legs. Start, stop altitudes and rates are definable for each leg. A profile can then be executed to simulate a complete landing approach including flare out or a take-off and departure.

RF Coupling - The supplied antenna couplers allow the radio altitude system to be quickly verified without access being required to test ports on the UUT LRU. The RF looped test verifies TX frequency, power, sweep rate, and RF level control provides the means to test UUT sensitivity.

Setup - The setup page allows system, user and RF connection parameters to be set by the user, including RS-232, AID, RF cable loss and altitude offset.

Available through your GSA Supplier

Unlike other testers, the ALT-8000 tests from the antenna to the indicator in the cockpit, allowing the operator to replicate in-flight conditions and isolate a bad component of the installed system.

- Tests FMCW radio altimeters including CDF types

- Tests pulse radio altimeters (non-pulse compression types)

- Direct-connect to UUT T/R or to installed system via antenna couplers

- Full RF loop test allows TX, RX, Antenna or Feeder faults to be identified

- Multi-channel operation (via additional test sets)

- Programmable multi-leg climb/descend profiles

- Large touch-screen display with simple user interface

- Remote control interface USB/LAN

- Lightweight and compact about 10 lbs. (4.5 kg)

- Battery 4 hours plus duration

Software-Downloads

Applications

- Terrain Awareness Warning System (TAWS) installations

- Create profiles to control dynamic altitude simulations

- Simulate a complete landing approach, including a flare out

- Simulate a takeoff and departure

- Replicate actual airborne conditions

Size

- Test set only 10.6”H x 13.9”W x 3.4”D (27.0 cm x 35.5 cm x 8.7 cm)

- With standard access 12” H x 30.5”W x 22.5”D (30.5 cm x 77.5 cm x 57.2 cm)

- 15.5 lbs. (test set only)

Standard Accessories

- 139137 Transit case

- 67374 Power supply

- 62401 Cable, TNC-TNC, 12” (Loop Back)

- 38353 TNC-TNC adapter (qty 2)

- 139139 Antenna coupler (qty 2)

- 139152 Antenna coupler pole set (qty 2)

- 88511 Coax, RG400, TNC-TNC, yellow 20’

- 89527 Coax, RG400, TNC-TNC, red 20’

- 112036 Attenuator, fixed 20 db

- 62302 Power cord, U.S

- 64020 Power cord, European

- 88035 Operation Manual (CD)

- 88036 Getting Started Manual

Optional Accessories

- 88500 Low loss RF coax cable 100 ft. (qty 2) w/ soft-side case

- 86196 Spare battery pack

- 89022 Maintenance Manual CD

- 91253 Coax RG400 TNC-TNC yellow 4’

- 91255 Coax RG400 TNC-TNC red 4’

Anwendungsbeschreibungen

Auswahlhilfen

Broschüren

Datenblätter

Handbücher und Bedienungsanleitungen

Kurzanleitungen

Software-Downloads

Software-/Firmware-Versionen

-

Avionics Maintenance and Repair Care Plans

VIAVI offers warranty and Avionics Maintenance and Repair Care Plans that include hardware and labor costs for repair, and annual certified calibrations performed at the factory during the duration of the service contract.

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards

Wir stehen Ihnen immer zur Seite

Bei uns erhalten Sie den Support, die Services, die umfassenden Schulungen und die Ressourcen, die Sie benötigen. Diese Leistungen tragen zur Maximierung Ihrer VIAVI Investitionen bei.

Wir helfen Ihnen gern

Wir sind dafür da, Ihnen zu helfen.