Automatic Dependent Surveillance Broadcast (ADS-B) Compliance

Your source for ADS-B performance testing

From factory to flight line, VIAVI offers test equipment to assist with the performance validation of ADS-B systems in a factory/lab environment or installed on the aircraft.

Produkte

-

AVX-10K Flight Line Test Set

Leistungsüberprüfung kritischer Bordsysteme mit einem kompakten Tester.

-

IFR6015 Military Flight Line Test Set

Supports military IFF transponder modes and TACAN

-

GPSG-1000 Portable Satellite Simulator

High-end test capability ideal for validating the performance of GPS enabled devices

-

IFF-45TSL MK XIIB and TACAN Bench Test Set

A next-generation RF signal generator/receiver designed for engineering design, certification, manufacturing, and…

-

IFF-45TS MK XIIA/TACAN Bench Test Set

Provides RF signal generation and parametric measurement of MK XIIA and TACAN equipment

-

ADS-B INTEGRITY Test Application

Performance testing of ADS-B Out equipment

-

RGS-2000NG NextGen TCAS Test Set

Designed for engineering development, design validation, manufacturing and return-to-service TCAS testing

-

ATC-5000NG NextGen Transponder/DME Test Set and ADS-B Target Generator

Prepare for Global ATC Modernization with NextGen test technology

-

F-16 IFF Antenna Coupler Kit

Reliably performs radiated power and transponder minimum trigger (MTL) level testing in multi-path ramp and hangar…

-

UC-584 Series Transponder Antenna Coupler

Providing repeatable test results on the ramp or in the hangar

-

TC-201 TCAS/Transponder Directional Antenna Couplers

Combined TCAS and transponder directional antenna couplers for the avionics maintenance industry

-

GC-130 GPS Antenna Coupler Kit

Solves the problem of poor GPS coverage in hangar environments or when a simulated static or dynamic GPS signal is…

A new age in air traffic management has arrived with FAA and EASA-Mandated Automatic Dependent Surveillance-Broadcast (ADS-B) capabilities. VIAVI Solutions is leading the way in this transition with test equipment offerings that fully support ADS-B performance testing at all phases of development and production. From avionics equipment R&D and factory testing to finished air frame ADS-B system testing, the breadth of VIAVI’s ADS-B test equipment has instilled industry leading organizations with confidence in successful, compliant and safe ADS-B performance throughout the multi-tiered aviation supply chain.

Behind the compliance-driven urgency for ADS-B testing lies a paradigm shift in air-traffic technology that will minimize the need for ground-based radar while improving overall safety and throughput. While other available test equipment can ensure conformance to the same stringent regulatory and performance testing specifications, only the VIAVI ADS-B test portfolio has forged the elite combination of feature sets, user interface enhancements and customer support that enables seamless ADS-B integration with unparalleled efficiency. VIAVI also supports the strict ADS-B testing requirements inherent to legacy aircraft servicing and retrofitting.

What is ADS-B?

Automatic Dependent Surveillance Broadcast (ADS-B) is part of a comprehensive transformation of air traffic control (ATC) practices that leverages emerging GPS, satellite and computer processing capabilities to gradually phase out the reliance on radar that has been an aviation cornerstone for decades. ADS-B compliance requires each pilot to automatically self-report their GPS position, using networking technology to make this information available to controllers and other pilots. The acronym ADS-B is therefore based on this Automatic reporting, Dependency on GPS and ADS-B Out transmitters, improved Surveillance capability created for ATC and Broadcasted positional data.

Each ADS-B system includes two essential avionics components. The satellite navigation source (GPS) and the transmitter (transponder) that communicates the essential aircraft information in frequent intervals to a network of ground stations. This transmitted data includes the position as well as the speed, heading, altitude and call sign. Emergency codes can also be activated and broadcast using ADS-B.

Although the term NextGen is sometimes used interchangeably with ADS-B, the Next Generation Transportation System is actually an all-encompassing air transportation modernization effort, including ADS-B as well as other innovations like Performance Based Navigation (PBN) and System Wide Information Management (SWIM), which will continue to roll out over the next decade and beyond.

The precise positional information imparted by ADS-B compliance leads to greater efficiency and improvement in many categories, including optimized aircraft spacing, more direct routing and better situational awareness for air traffic controllers and pilots.

The enhanced level of shared data allows pilots to more accurately assess the position of other aircraft and receive real-time warnings or redirection. This creates a significantly improved safety profile with callouts no longer subject to latency constraints and error levels minimized. Unlike radar, ADS-B can also monitor air traffic at very low altitudes or on the ground, so inadvertent runway incursions become appreciably less likely.

In addition to real-time weather reporting, ADS-B In also provides other supplementary information to pilots, such as runway closures, flight restrictions and terrain maps for low visibility areas, all of which further augment safety and efficiency.

Ground stations are cheaper and easier to place than radar deployments, so the amount of coverage provided can be easily expanded. The technology shift from radar to GPS also provides inherent benefits in navigation and fuel efficiency, since flying over ground-based radar stations to support ATC check points will no longer be necessary and more direct routing can be implemented.

ADS-B capability has been mandated by the FAA for aircraft flying within controlled airspace over the continental United States and select class E airspace over the Gulf of Mexico. Controlled airspace is defined as class A, B and C airspace or class E airspace above 10,000 feet. Class A airspace is characterized primarily by altitude, while class B, C and E airspace zones are further defined by airport proximity and location.

ADS-B compliance is required by January 1, 2020, unless an ATC deviation has been approved in advance. In addition to airliners, helicopters, turboprops and private jets must also be equipped with ADS-B transponders. The FAA has provided financial assistance in the form of rebates to offset some of the conversion cost burden on individual operators.

Complete details of the FAA’s ADS-B compliance rules can be found in released Code of Federal Regulations (CFR) publications. ADS-B regulation 14 CFR § 91.225 provides specifics on the impacted airspace and regulation 14 CFR § 91.227 defines the performance standards for the ADS-B transponder and positioning device (GPS).

International ADS-B compliance regulations are rolling out at a complementary pace. Most Asian nations with significant air traffic already require 1090ES (Extended Squitter), while Europe and Canada are also mandating compliance, although at a slightly less aggressive pace.

ADS-B technology includes two distinct communication paths. ADS-B Out refers to the transmission of GPS data from the aircraft to ground-based ATC stations. ADS-B In is an optional deployment of inbound communication technology that furnishes pilots with weather, traffic and other valuable information. Only ADS-B Out capability is mandated by FAA regulations.

ADS-B Out

The ADS-B Out equipment is what the aircraft uses to continuously transmit precise position information and other flight data. This unidirectional dissemination is required for ADS-B compliance with data broadcasted once per second. Either a 1090 MHz extended squitter (ES) or a dedicated 978 MHz universal access transceiver (UAT) can be installed to suit this application, along with a WAAS enabled GPS device.

All aircraft flying in class A airspace are required to operate on the 1090ES MHz frequency, making this the logical choice for commercial airliners, and all ADS-B Out equipment must be permanently (panel) installed.

ADS-B In

As the name suggests, ADS-B In technology allows the pilot to receive subscription-free information including air traffic and weather from ground stations or other pilots. ADS-In capability is optional and therefore not included in the ADS-B compliance regulations published by the FAA.

The ADS-B In receiver can also enable the pilot to view the ADS-B Out information of other aircraft, using a computer screen or portable tablet. Although ADS-B In is not mandated, the benefits garnered from this option can greatly enhance situational awareness and safety levels. Portable ADS-B In only devices are available, along with comprehensive ADS-B In/Out products that integrate both communication modes.

Without adequate testing, the safety and efficiency benefits of ADS-B cannot be fully realized. The FAA’s public ADS-B PAPR (Performance Report) tool is used to verify ADS-B compliance of an airborne deployment simply by providing basic aircraft information online and requesting the test.

The FAA report details any specific areas that failed to meet performance requirements and any incorrect avionics settings that are detected. Some of the more common issues observed include missing barometric pressure altitude, flight ID issues and position “jumping” errors.

Before this airborne testing is performed, it is a recommended practice to utilize an ADS-B test set on the ground to ensure a passing result will be obtained during the official certification testing. This includes testing the transponder and receiver separately, then again at the system level to verify compatibility. ADS-B test equipment is versatile enough to suit all levels of manufacturing and deployment is an invaluable element of this ground testing.

For testing at the R&D, factory test, or return-to-service level, ADS-B test equipment with flexible emulation capabilities can facilitate robust testing of avionics components prior to installation. The ATC-5000NG, for commercial applications, and the IFF-45TS, for military applications, either a ground transponder or an airborne interrogator, making this powerful platform an industry-wide standard for avionics OEMs.

Transponder testing for extender squitter and UAT equipment types is an essential element of ADS-B compliance testing. Comprehensive test coverage includes sensitivity, frequency and power as well as transponder performance in the simulated airborne environment.

Building on nearly 50 years of providing superior avionics test sets, the AVX-10K is a compact, durable tester capable of providing a wide range of quick airborne system auto-tests and in-depth troubleshooting using software specific applications.

The GPS-1000 portable satellite simulator is an easy-to-use test device that can create 3D WAAS GPS simulations to support ADS-B testing. The GPS-1000 allows the user to simulate a position in lieu of using unreliable repeaters or moving the aircraft outside or to a surveyed location. In addition to providing a GPS source, the GPSG-1000 can be used to test the aircraft’s GPS receiver and to support testing of any other airborne system that requires a GPS input. The GPS-1000 features upgradable software and unlimited simulated navigation plan storage.

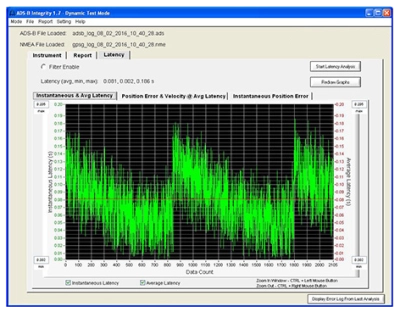

Although the IFR6000 provides for an easy ADS-B test to AC 20-165 requirements, when combined with the ADS-B INTEGRITY Test App, the user can now perform cross checks to assure the installed transponder is properly configured. Improper configuration is the cause of most non-performing equipment (NPI) issues identified by the FAA. By including the GPSG-1000 as part of the test, a dynamic not found in any other test solution is added. The GPSG-1000 will allow the user to ‘test in place’, meaning not having to move the aircraft outside, to a surveyed location, or rely on repeaters that can be problematic or cause interference with nearby aircraft. The GPSG-1000, with the ADS-B INTEGRITY Test App, can simulate a flight path and provide a full performance report of AC 20-165B requirements, including latency analysis and positional error, which otherwise can only be accomplished by flying the aircraft.

Using Antenna Couplers will enhance safety by shielding RF Transmissions, meaning that your aircraft will not be visible on others’ radars. VIAVI offer various Antenna Coupler options – F-16 IFF Antenna Coupler Kit, UC-584 Series Transponder Antenna Coupler, and the TC-201A TCAS/Transponder Directional Antenna Coupler.

On-Demand Webinar From factory to flight line, VIAVI offers various solutions for ADS-B Performance Testing. In line with the EASA and the FAA ADS-B Out mandates, this webinar recording provides an overview to maintenance teams of airlines, repair stations and manufacturers on the best practices to follow when testing Transponders with ADS-B Capabilities.

Request instant access to the full recording or watch the short preview below.

Hi everyone. This is Hamish Stewart and I'm a business development manager for VIAVI Solutions. And I'm joined today by my colleague, Barry Beasley, who is an avionics product development manager.

During this webinar, I'm going to give an overview of the following. Firstly, ADS-B technology, in terms of what it is, the benefits that it brings and how it has developed over time. I'll then talk a little bit about the EASA mandates covering ADS-B transponders, and what the recent changes to that are. The bulk of the webinar will be about the things that you should be aware of when testing ADS-B systems, and what we and many of our customers believe to be the testing best practices to follow. I'll then give a brief introduction to the VIAVI products which can be used to ensure safe, reliable, and efficient ADS-B testing.

Before I go into that, though, I'd like to give you a quick overview of who VIAVI Solutions is and why we're qualified to talk about avionics testing. VIAVI Solutions, created from JDSU, was founded in 1923 as Wandel and Goltermann by two technicians building and selling radios. Through investment and acquisition of key technologies and other companies, we have grown into one of the world's largest electronic test and measurement companies. With the acquisition of Cobham's AvComm division in 2018, VIAVI catapulted itself to the forefront of avionics testing. Cobham itself had acquired the AvComm business as part of its 2014 purchase of Aeroflex, a name synonymous with the avionics industry that can trace its roots back to the company's JcAir and IFR systems. The AvComm business is still, in fact, based in Wichita, Kansas, where IFR started, and many of our AvComm employees have been with the business for decades.

So now that you know who we are, let me give you a brief overview of what ADS-B is.

What is ADS-B?

ADS-B can be defined as a Mode S transponder-based surveillance technique that relies upon aircraft or airport vehicles broadcasting their identity, position, and other information derived from onboard systems such as GNSS receivers or altimeters. The signal can be captured for surveillance purposes on the ground, that's referred to as "ADS-B out", or onboard other aircraft, referred to as "ADS-B in". The latter can facilitate airborne and ground situational awareness, to aidspacing and separation of aircraft.

The A within ADS-B stands for automatic, because unlike previous transponders technologies like Mode A or Mode C, no external stimulus on interrogation is required for an ADS-B transponder to transmit signals out. These unsolicited down-link transmissions from an ADS-B Mode S transponder are referred to as squitter.

The D in ADS-B stands for dependent, because it relies upon onboard systems to provide surveillance information, the S in ADS-B, to other parties. Finally, the B in ADS-B refers to the fact that the data is broadcast, i.e. the source transponder itself has no knowledge of who receives the data, and there is no interrogation or two-way contract between it and the receiving device.

ADS-B is seen as a key enabler of the future of air traffic management networks, contributing to the achievement of the Single European Sky performance objectives, including safety, capacity, efficiency and environmental sustainability.

ADS-B Benefits

- Greater Efficiency: So what do we mean by greater efficiency from an ADS-B transponder? So efficiency savings can be achieved both on the ground and in the air when the aircraft are equipped with ADS-B transponders. At airports a locally optimized mix of available technologies i.e. airport multilateration, surface movement radars, and ADS-B out will enable advanced guidance and control for optimized aircraft spacing that can be part of an integrated airport operation. In the sky, if an aircraft is equipped with ADS-B in, and a means to effectively display available surrounding traffic information to the pilot, then airborne self-separation can be optimized. Pilots can have better situational awareness.

- Increased Safety: In terms of increased safety, the enhanced level of shared data that ADS-B enables all those pilots to more accurately assess the position of other aircraft and receive real-time warnings or redirection. This creates a significantly improved safety profile with call-outs no longer subject to latency constraints, and error levels are minimized. ADS-B can also monitor air traffic at very low altitudes or on the ground. So inadvertent runway incursions become appreciably less likely.

- Advanced Information: There’s also an ability to provide advanced information. So in addition to real-time weather reporting, ADS-B in also provides other supplementary information for pilots, such as runway closures, flight restrictions and terrain maps for low visibility areas, all of which further augment the safety and efficiency of ADS-B-enabled aircraft.

Mode S Transponder Development

As I mentioned earlier, ADS-B is a Mode S transponder-based surveillance technique, and the table here shows how Mode S transponder functionality has changed over the years. It has gone from being a basic interrogator-based system, reporting things such as altitude and aircraft codes, to an automatic broadcast system, which allows much more information to be reported to the ground and shared within the sky.

ADS-B Around the World

Now, ADS-B has existed as a technology for many years, as many of you will know, and as you probably know it's in use within Europe and around the world already. Now, different regions and countries have mandated the use of ADS-B transponders on aircraft flying within their airspace at different dates throughout the last few years, and the table here shows the status of each of these. You will see that within Europe, the deadline for implementation of ADS-B within specified aircraft is now the 7th of December 2020, a recent change to the original date, which was the 7th of June 2020.

EASA ED-102A(DO-260B) / CS-ACNS Section 4

Within Europe, EASA, the European Union Aviation Safety Agency, develops common safety rules at this European level, and it monitors the implementation of standards. Their certification specifications for airborne communication, navigation and surveillance known as CS-ACNS, which were originally published in December 2013, have a Section, 4, which details the requirements of the ADS-B extended squitter messaging. In terms of which aircraft these regulations apply to, all aircraft weighing more than 5,700 kilograms or all aircraft that have a maximum cruise speed of greater than 250 knots, have to be equipped with ADS-B out. The original date for aircraft to have this was 7th of June 2020, but this has recently changed to be 7th of December 2020.

There are some transitional agreements and exemptions to that, as detailed in the table shown <download full recording to see table>. Notably, in terms of transitional agreements in place, any aircraft which had its first certificate of airworthiness issued between the 7th of June 1995 and the 7th of December 2020, and which is part of a retrofit program, which means it will be compliant by 7th of June 2023, are exempt from this 7th of December 2020 date. Exemptions are also in place for aircraft with a certificate of airworthiness which was issued before the 7th of June 1995 or for aircraft which will be retired by the 31st of October 2025.

ADS-B Mandate: Europe vs USA

Quite often, European mandate is compared to the one in the USA, which came into effect at the 1st of January this year. And there are some slight differences between these mandates, which are shown in the table <download full recording to see table>. These may be relatively minor differences, but they're important to be aware of if you are involved in the certification or testing of aircraft which could be flying between both continents.

ADS-B Implementation Status: Europe

So what does this all mean in terms of aircraft within Europe? So the number of aircraft that this affects within the European fleet is roughly 7,500. And the good news is that around 5,250, or 70% of them, are already equipped. That does mean, however, that over 2000 aircraft still need to be equipped with ADS-B. Out of those still to be equipped, it's estimated that around 10% of them will fail their initial testing after the equipment is installed. So efficient testing is an absolute must if you want to ensure your ADS-B installations are safe and secure.

ADS-B Testing Best Practices I'm going to talk about the ADS-B testing best practices. Now, these are things that we deem to be essential to ensure safe, reliable, and efficient testing of your transponders.

- Before the Test: So, first of all, there are a couple of things that you need to do before you start testing. One of the most important things is to consult the aircraft maintenance manual for the aircraft that you're testing, particularly for wide-bodied aircraft platforms. These can have many different testing requirements, and the aircraft often needs to be put into a specific mode for testing. Similarly, there are regular two-year maintenance testing cycles mandated by EASA, and the schedules for these are in the CS-ACNS documents for retrofit of ADS-B transponders.

Also, within some of the EASA documentation is the appendix to some of the safety information bulletins that are out there. So with particular identification of the Appendix 1 safety information bulletin in 2011-15R2, you can see that that recommends that you contact the local air traffic control unit and advise them of your intention to conduct transponder testing. So when you're doing that, you'll need to tell them the start time and the test duration, and you'll also need to inform them of the altitudes which you'll be testing, your intended aircraft identification and what your intended Mode A code is. So all of this needs to be done before the test. - Transponder Tester: And then most importantly, what you will need for transponder testing as a transponder test set. And to test these installations and to ensure the system performance is as required, you will need a transponder test set which has the option to test ADS-B out specifically. There will then be various checks done to ensure that your equipment is specified within the test equipment to determine any non-performing issues. Doing this will ensure that you have safe, reliable, and efficient ADS-B testing.

Common ADS-B System Failure Issues: Things to look out for when you're doing the testing are such things as missing data, and that can be data from the sub-systems within your aircraft that feed into the transponder, or something within the qualification of the data that means the transponder does not send it on.

The next group of things that we want to look out for are GNSS integrity and accuracy issues. And it's important to note that when you're talking about GPS signals and talking about the signals that are reported out of your ADS-B transponder, they're not always called the same thing in GPS terminology as they're called in transponder terminology.

Other types of things to look out for are where installations may have gone wrong. And that could be something as simple as the address being wrong because some pins have been set incorrectly within a transponder. It might be a flight ID mismatch, typically caused by pilot data entry errors, or it could be missing Mode 3 or Mode A codes. And there's also the issue of the aircraft on the ground, i.e. not reporting that it's on the ground correctly. And again, this can be caused by switches such as those on the altimeters not being in the airborne state when the ADS-B testing is done.

- Transponder Test Setup: So, first of all, you want to set up your transponder, and there are some general points that you should look out for when doing this. In terms of the antenna that's being tested, quite often, there will be antennae either on the top or on the bottom of the aircraft. So you need to specify which one you're using. In terms of the RF port that you're connected to, there are a few ways of connecting to this. So you can either use a tester which has an antenna, and you can be testing over the air to the antenna on the aircraft itself, you can be directly coupled to the transponder connection on the aircraft antenna if you've removed the antenna, or you can have the antenna on the aircraft in place and you can connect to that direct with a coupler. You also need to know what the antenna range and height is. Specifically, if you're using a test set with an antenna to connect over the air to the aircraft, you need to be within the range of it to be operating correctly. And then also, if you're using a direct connection or a connection with a coupler, it's important for you to specify the cable length, the cable loss, and even the coupler loss if you're using a coupler.

- UUT Address: The next thing to look out for is the UUT address. Now, if you're within testing distance of a number of aircraft, and you're performing over-the-air tests, you should use the UUT manual addressing mode, and that avoids you getting multiple replies to the test calls from the test set when you send out the all-call acquisition message. And you have to note that the aircraft within the test area need to be in the airborne state for testing. So again, you will need to refer to the aircraft maintenance manual for that information to ensure that your aircraft is ready to test as well as your transponder tester and your transponder being ready to test.

- ADS-B Monitor: Often the parameters that have to be tested are spread across a number of different binary data store registers. Also note that the geometric altitude is referenced from the GNSS signal received and is referenced to mean sea-level in the area that you're performing the test at. One other thing to note when you're doing the ADS-B testing is that you need to calibrate the barometric pressure gauges on the aircraft before you do the aircraft testing.

- Advisory Circular On some testers, there's an auto-test screen that allows you to test all of the parameters required by the regulations and give you those in one nice, simple screen to allow you to tell if the test has passed or if it's failed. And for the EASA tests that are mandated, we've got an automatic test on our equipment that gives you coverage of about 95% of the testing all in one place, and the other 5% can easily be accessed on a couple of different screens within the tester.

- Power and Frequency: One of the things that often fails is the power and frequency that's coming out of the transponder. Now, this can be due to a number of things such as improperly being set up. It can be due to multi-path or reflection issues within the hangar or the environment that you're testing. And it could also be that you've got the antenna gain parameters set up incorrectly. Now, the best solution to avoid this type of issue is to use an antenna coupler, which washes out the antenna gain and takes care of any reflection or multi-path issues which you may be seeing.

- Antenna Transmission Covers: So the use of antenna couplers ensures safety whilst you're testing because it shields that RF transmission from the aircraft and it ensures that it's just that signal which is going into your test set. And it ensures that the signals coming from the test set are the only ones which are going into your aircraft. Now, this is actually advised by EASA in safety information bulletin 2011-15R2. And it's also advised by the FAA and SAFO 17002.

Now why is this specified or advised within these documents? Well, essentially this is to ensure that you have no false intruder situations. So you will see here on the bottom right hand side of the screen, you've got your hangar where you have your aircraft that are being tested. Now typically this will be close to an air traffic control tower, and it will have aircraft flying overhead. So with the proper use of couplers to do the testing, that essentially shields your aircraft on the ground, and it stops it from appearing as if it's in the sky as it goes to the aircraft. So if that ghost aircraft appears in the sky when it's actually on the ground, that can cause problems for both air traffic control and for other pilots. And you can see here that the EASA safety information bulletin 2011-15R2, in Appendix 1 it actually recommends the use of transmission covers whether or not testing is performed inside or outside of a hangar. - ADS-B -- GNSS Position Decode: So, going back to other things to look out for when you're testing ADS-B installations. So the aircraft GPS needs to have a clear view of the sky or the GPS constellation to generate a good horizontal protection limit NIC value. Normally, testing results inside a hangar are not acceptable due to satellite blocking and multi-path. So there are ways of getting around this. You can either move your aircraft outside the hangar, or you can use GPS repeaters within the hangar. Another way of doing this, or avoiding these issues, is to use a GNSS simulator, and this can be a cost-effective alternative to using a live constellation or having to go to the cost of moving your aircraft outside of the hangar to a known reference location.

- GPS Simulation: So when it comes to GPS simulation, how does that ensure a reliable test? Well, the first thing is it allows a user to generate a reliable static GPS signal whilst not in direct line of sight of the satellite systems, i.e. inside the hangar. Coupled with that, it also allows a user to simulate flight path information, to perform dynamic testing for checking latency issues within the transponder system. This also allows you to show that the GPS on the aircraft is working at various locations and not just in the one where the aircraft is positioned whilst doing the test. And again, it also eliminates the GPS repeater errors which can be seen when you're using the aircraft in a hangar on a surveyed location.

- GPS Accuracy & Integrity Reporting: When working with GPS simulators, it's important to note that the naming conventions used by GPS systems and those by ADS-B transponders differ slightly. But the key things to note for both are that GPS accuracy and reported accuracy are the things that you should be looking out for. GPS accuracy is dependent on a number of factors, such as the user equivalent range errors, including ionospheric defects, Ephemeris errors, satellite clock errors, multi-path errors, etc, and satellite geometry and all of these are line-of-sight errors.

Now when it comes to reported accuracy and integrity, which for GPS receivers which are not SA aware, the accuracy and integrity reported and then used in ADS-B messages is based on an assumed value of UERE corresponding to the period when the ASA was active. This value can be grossly larger than the accuracy of the positional data delivered now that the SA is inactive. So it's important to be aware of all of these things when you're testing your transponder to ensure that your GPS accuracy and integrity is reported correctly. The use of a GPS simulator is the best way to do this, because you can have control over all of these parameters that are going into your transponder so that you know exactly what they are, and you should know exactly what they should be when they come out of the transponder. - Automation Software: One other thing that can also be used to ensure efficient ADS-B testing is automation software. So in terms of automation software, this can reduce the test time, because often the ADS-B testing involves setting up lots of things manually, both inside the aircraft and on the transponder tester. And if you can have some software which can automate all of this, that can greatly reduce your test time. In the same manner, this can also eliminate manual errors, which are often experienced by users when they are imputing data into the test set. And again, if you're able to not move your aircraft out of the hangar and do some automated testing in the hangar, it allows you to save on the fuel costs. And finally, by using automation software, you can generate the test report automatically, which again is more efficient.

- Automation Software -- System Overview: So what would the automation software system look like? So you've got your aircraft or your unit under test, and the first thing that you need is a transponder tester. You can then have that connected via a coupler to the antenna, which is connected to your ADS-B transponder. And again, to make things reliable, we'll just say that we can have a GNSS simulator. And again, we will have that connected to aircraft via a coupler to ensure that the signals are shielded and not affected by any multi-path issues. We can then connect both of these devices up to a laptop or a PC and run some automation software. And that allows us to quickly, efficiently and reliably produce a compliance report that will show how the ADS-B system has been tested on your aircraft.

ADS-B Performance Testing Products from VIAVI

Okay, so the next thing we're going to talk about very briefly is the VIAVI Solutions ADS-B performance testing products. So first and foremost, something that you may be aware of is that we have the IFR6000 and IFR6015 transponder tester, and this is the most widely used flight-line tester today. And as you can see from the screenshot here on our website, we have various training videos available on the VIAVI webpage of how to use this. And coupled with that, we also have our antenna couplers.

Now we'll review the different ADS-B performance testing products that we have available at VIAVI.

- Transponder Tester: So the first thing is the transponders tester. Now, we have two versions of this, the IFR6000 and the IFR6015. So the 6000 is targeted at the commercial market and the 6015 is targeted at the military market. And on our website, if you go there you can see some nice how-to videos on how to use the equipment for doing various different tests related to navigation and communication equipment within your aircraft.

- Transmission Covers & Antenna Couplers: We also have a range of transmission covers or antenna couplers, which can be used for ADS-B testing, can be used for TCAS testing.

- GPS Simulator: We have also a GPS simulator called the GPSG-1000, and again, like our other products, you can find more information about this on our website, where you'll see application notes, brochures, data sheets, software and firmware release notes, and some technical papers on how to use it and what the technology is about.

- ADS-B Integrity Test Application: And finally, we have our automation software called ADS-B integrity test application. And we actually have a free software download for this, where you can download a demo version of this from our website to just get a feel for the types of things that you can test using this in an automated environment. So again, there are four main products that we have for testing ADS-B compliance to ensure safe, reliable, and efficient-

ADS-B Takes Off

After a decade of discussion, development and refinement, ADS-B compliance is no longer just a convenient integration of modern technology to improve air traffic safety and throughput. It has become the mandated ATC communication mode for commercial flights in the U.S and ultimately worldwide. Radar technology established an exceptional track record for safety and reliability over the past century, yet the preeminence of satellite GPS and modern networking architecture can no longer be denied.

Aviation industry growing pains have underscored a remarkable opportunity for safer, more efficient air travel through ADS-B Out regulation and an information bonanza for pilots through this new technology. Throughout this transition, industry leading ADS-B test equipment will play a pivotal role in the overall success of ADS-B from the engineering lab to the skies.

Wir stehen Ihnen immer zur Seite

Bei uns erhalten Sie den Support, die Services, die umfassenden Schulungen und die Ressourcen, die Sie benötigen. Diese Leistungen tragen zur Maximierung Ihrer VIAVI Investitionen bei.

Fragen Sie einen Experten

Wenden Sie sich an uns, wenn Sie mehr Informationen oder ein Preisangebot wünschen. Bei uns finden Sie die Experten, die alle Ihre Fragen beantworten können.