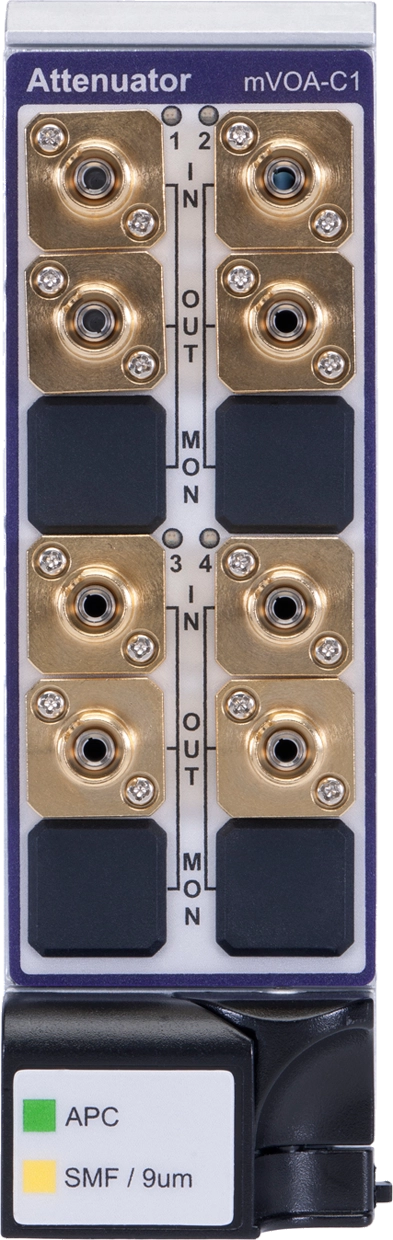

The Multiple Application Platform (MAP) Variable Optical Attenuator (mVOA-C1) is optimized for the industry-leading VIAVI MAP-200 platform. Based on the previous-generation Multiple Application Platform (MAP), the MAP-200 is the first photonic layer lab and manufacturing platform that is LAN Extensions for Instrumentation (LXI)-compliant by conforming to the required physical attributes, Ethernet connectivity, and interchangeable virtual instrument (IVI) drivers. The MAP-200 platform is optimized for density and maximum configurability to meet specific application requirements in the smallest possible foot print.

The mVOA-C1 is a stepper motor and filter based attenuator that takes advantage of the latest available technologies to provide the highest performance optical power level control solution with the lowest optical impairments.

- Ultra low insertion loss to minimize loss budget utilization

- High accuracy and high repeatability to reduce measurement uncertainty

- Fast transition speed to reduce testing time

- Flat spectral response to reduce wavelength dependent uncertainty in multi-wavelength applications (CWDM, DWDM)

- Low backreflection to reduce instabilities due to reflected light

- Optional built-in wavelength calibrated power meter reduces the uncertainty by reducing external connections

- High input power capability for EDFA testing and multi-wavelength applications

-

MAP-220C Multiple Application Platform

Provides a flexible, more cost-effective compact platform for optical test switching and signal conditioning in optical device and sub-system development and manufacturing.

-

MAP-300 Multiple Application Platform

Third Generation optical test and measurement system that is optimized for compact cost-effective development and manufacturing of optical communications technology.

Software-Downloads

Literatur

Anwendungsbeschreibungen

Datenblätter

Auswahlhilfen

Whitepaper und Bücher

Software-Downloads

Care Support Plans

| Product Group | Recommended Plan | Bronze | Silver | Maxcare | |

|---|---|---|---|---|---|

| MAP (Mainframe/Module) | Bronze-3 | Does the product require calibration? Common questions or issues |

-

VIAVI Care Support

Services Bronze Silver MaxCare Bild Bild

Bild Bild

Bild

Technical Assistance Premium Premium Premium Factory Repair Priority Service Self-paced Training Factory Calibration Express Loaner * 5-year plans only; if applicable

-

VIAVI Care Support for Existing Equipment

FleetCare plans can be customized to include any service entitlements on your fleet of existing equipment. Please fill out a Service Contracts form for a quote.

- Any collection instruments with a single coterminous renewal date

- Each contract is customized with any number of annual terms required by the customer

- Onsite Calibration, Training, Field Application Engineer days can be added

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards

Verwandte Produkte

Wir stehen Ihnen immer zur Seite

Bei uns erhalten Sie den Support, die Services, die umfassenden Schulungen und die Ressourcen, die Sie benötigen. Diese Leistungen tragen zur Maximierung Ihrer VIAVI Investitionen bei.

Wir helfen Ihnen gern

Wir sind dafür da, Ihnen zu helfen.