What is Fiber Construction?

Learn all about the fiber network construction process and how it unites experts in many areas.

The fiber optic network construction process is a cross-functional effort that brings together experts in optical network design, construction, and testing. The basic building blocks of a fiber construction project include:

- Underground cables: Fiber cables are usually buried 3-4 feet below the surface, with heavy construction equipment used to complete the trench digging. Trenches may be slightly deeper in colder climates to protect from freezing temperatures. Microtrenching (8”-16” deep) is sometimes used to avoid disrupting infrastructure or natural habitats. Extreme care must be exercised during this process to avoid existing fibers, water or gas pipes and power lines.

- Conduit placement: The fiber optic cabling is routed through plastic or steel tubing sections designed to protect and organize buried optical fiber runs. Specialized fiber optic construction equipment like the Ditch Witch save valuable time by placing conduit as they dig the trench. Once the conduit is in position, the fiber optic cable is carefully pulled or blown through.

- Aerial Fiber links: Above-ground optical fiber deployment using towers or poles is a more practical option in areas where the terrain is uneven or excessively rocky. Overlashing (attaching fiber cables to existing power cables) speeds up fiber construction by minimizing new pole construction and placement. Splice locations for aerial networks must be selected carefully to ensure they are accessible to technicians, vehicles, and equipment.

- Fiber termination: The proper termination of fiber runs at distribution hubs, patch panels or drop cabinets and is a critical element of fiber network construction. At these connection points between the fiber backbone and individual drop fibers, the quality of fiber hygiene, organization, and connections determine the long-term performance and efficiency of the network.

- Submarine cables: Despite the proliferation of satellite networks, over 95% of international data transfer is still completed via underwater fiber networks. Submerged fiber runs require specialized ships and fiber construction services to deploy them on the ocean floor. Several additional layers of insulation, gel, armor, and tubing are needed to protect fibers from damage due to water ingress, shifting currents, and fishing equipment.

The high capacity, low power consumption, and long-distance range of optical fiber has revolutionized wired communication and computer networking practices. Deploying fiber cabling underground, over aerial links above ground, or using submarine cables to span the oceans requires a set of tools and practices collectively known as fiber construction.

With new fiber networks carrying up to 1728 fiber strands in each cable, labor intensive trench digging, conduit placement, and pole attachment are just part of the fiber construction process. New fiber networks require a heightened attention to planning, certification, and cost control to effectively manage the unprecedented volume of fibers.

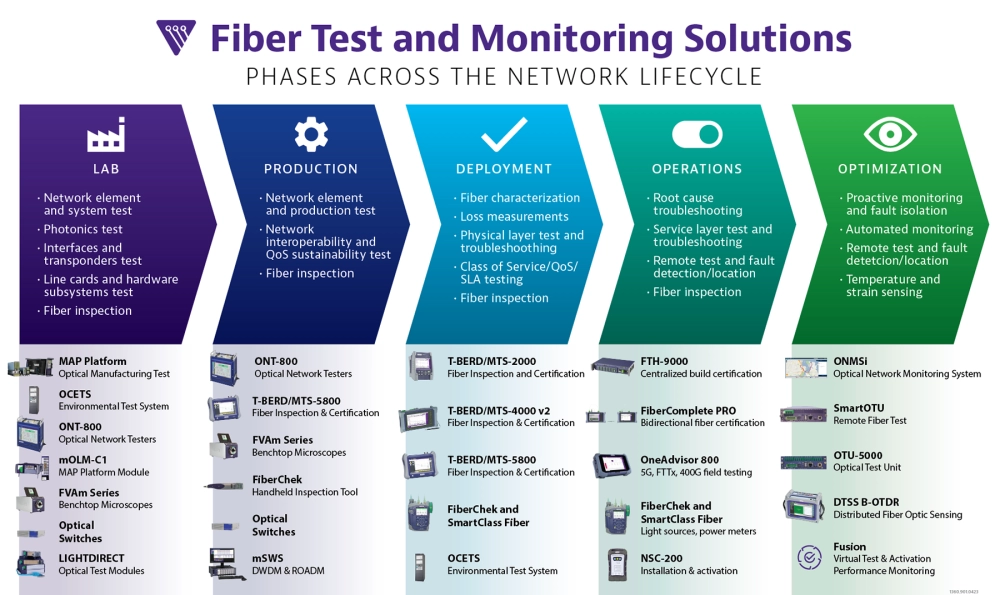

When the physical elements of fiber construction come to fruition, it is the result of successful design, planning, deployment, and activation phases. Fiber testing is an essential practice throughout the network lifecycle.

Fiber Network Construction Planning

Successful fiber construction begins with detailed planning. Like any large infrastructure project, planning must incorporate everything from landscape evaluation and mapping to permitting, supply chain, and technical resource availability. Cloud-based fiber network construction planning tools allow physical network inventory (PNI) and geographic information to be carried into the field as construction progress is tracked in real time.

Deployment

The “heavy lifting” of fiber network construction is completed during the deployment phase. This begins with cable and conduit placement in accordance with the network design and ultimately leads to the termination of each fully spliced link at the fiber distribution hub or patch panel. LC and SC are commonly used fiber connector types, while adoption of multi-fiber MPO connectors is increasing, especially in data centers and data center interconnects (campus DC).

Bidirectional testing

Fiber testing ensures the integrity of the fiber itself as well as all splices, connections, and termination points. Insertion loss (IL) and optical return loss (ORL) must remain within their specified budgets to prevent excessive bit error rates (BER) and unreliable transmission. Although IL is usually consistent when measured from either end of the link ORL and individual splice loss can vary, therefore preferable bidirectional test processes during fiber construction include:

- Bi-directional ORL measurement using an optical return loss meter to verify the quality and performance of the link.

- Bi-directional OTDR testing to certify links and pinpoint the position and cause of loss events while minimizing the erroneous results that can occur when splices are tested in only one direction. According to the testing standard ITU-T G.650.3: “Unidirectional OTDR test results can be used to roughly judge the splice quality, but accurate splice loss measurement must be based on the bidirectional OTDR test.”

- Automated test tools and cloud-based asset, test data, instrument configuration and job management solutions make these important bidirectional test processes more efficient, reliable and repeatable.

Activation

The activation phase of fiber construction is the critical transition between fiber network deployment and fiber network use by customers. Network equipment is provisioned, and live services are turned on. This entails comprehensive testing and validation to ensure all fiber links are secure and reliable. Once this important phase of fiber construction is completed, last mile FTTx drops can be installed with confidence to service individual homes or businesses.

Increased demand for fiber networks and expansion into new regions creates challenges for fiber construction services as they balance complexity, capacity, and cost constraints. These pressures are amplified by when unforeseen circumstances and resource issues lead to schedule delays.

Sourcing of materials

Sourcing of materials is an ongoing fiber optic construction challenge. Worldwide fiber shortages led to fiber price increases of up to 70% between 2021 and 2022. The expanding cloud/edge data center ecosystem and 5G deployment contributes to these challenges, with more competition for limited fiber resources. Plastic tubing, connectors, and optical fibers/cables needed to complete the fiber construction process have also been subject to widespread shortages and long lead times in recent years.

Fiber testing

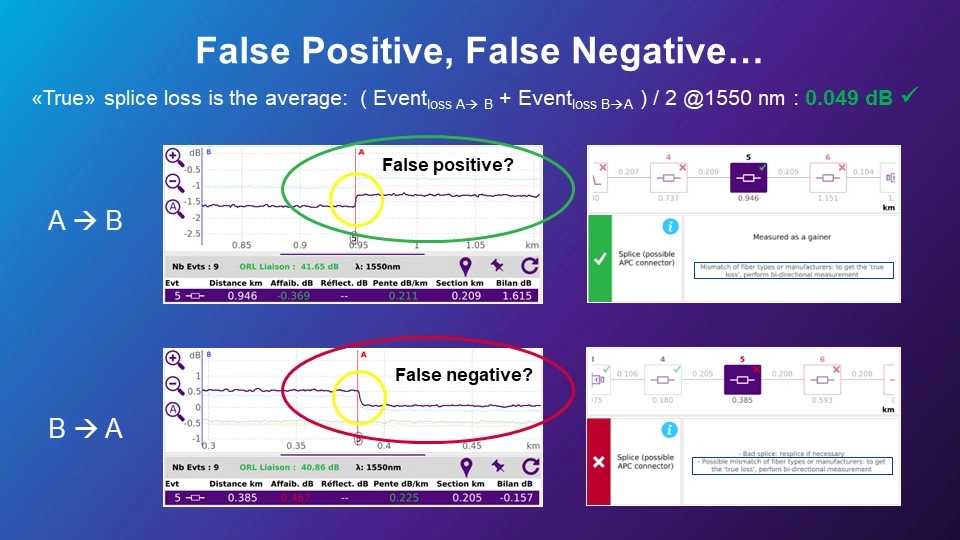

Fiber testing to ensure consistent physical properties as fiber sections are spliced together continues throughout the fiber construction process. Since the joining of mismatched fibers can induce signal loss or reflection issues that impact performance, the focuses on identifying and eliminating false negative or false positive test results caused by mismatched fiber through the use of bidirectional fiber network construction solutions.

Higher-density fiber cables

Fiber volume continues to increase as operators and service providers strive to increase their carrying capacity in a limited physical space. More fiber strands mean more complexity, with each strand multiplying splice, connection, and test times. Where 100 fiber strands might be tested in one day, cables with 1,000 strands or more could take over a week. Skilled technicians and automated, portable fiber test solutions help to mitigate these challenges.

Weather conditions

Weather conditions can create unpredictable yet unavoidable fiber construction challenges. Extreme temperatures, rain, snow, and high winds can be hazardous to the fiber as well as the construction personnel and equipment. A proactive approach to fiber network planning includes redundancy, weather-resistant material selection, regular maintenance, and fiber monitoring to ensure the network will remain operational and reliable in extreme weather conditions.

Given the long distances traversed, rising material prices, and high level of technical expertise required, it is not surprising that some cost estimates now exceed $60K per mile for an underground deployment. The most significant fiber construction costs are associated with:

Labor: Physical labor, including trench digging, splicing, connecting, and testing, is the largest expense incurred during fiber optic network construction. Collective labor costs can account for up to 60% of the overall project cost.

Terrain: The path chosen for fiber construction is a key driver of cost. Traversing mountains, waterways, or urban areas with a combination of underground and aerial construction adds cost and complexity. Right-of-way and permitting expenses also vary depending on the path selected.

Rework: During fiber construction, rework can become a significant cost consideration, adding unplanned time, labor, and material costs to the project. The impact becomes more significant in the later phases of construction. Automated, portable test tools and processes reduce rework by proactively identifying loss points and other fiber defects, comparing network designs to as-built results in real time, and verifying end-to-end fiber link integrity.