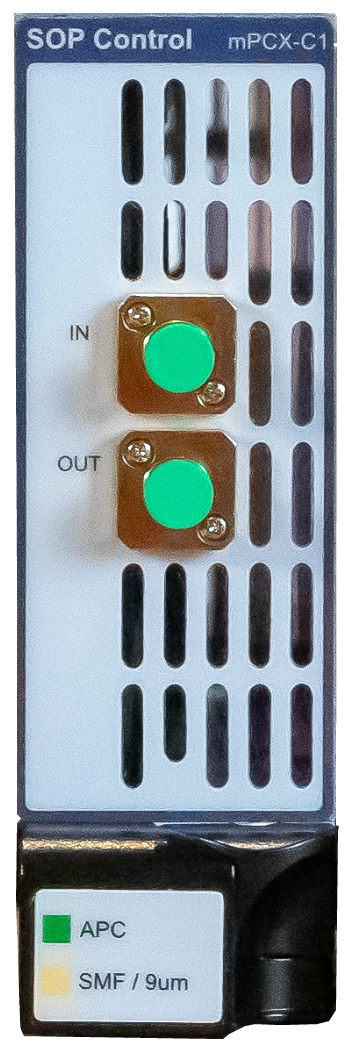

多应用平台 (MAP) 偏振控制模块 (mPCX-C1) 是一种单插槽高速偏振扰偏器、控制器和稳定器。 采用铌酸锂光电波片,响应时间可满足最严苛的偏振管理应用的要求。 随着相干调制格式和偏振复用系统的兴起,了解这些信号的偏振状态与单模光纤的相互作用方式成为了新的关注重点。 MPCX-C1 设计为可实现这些测试,不但可以在实验室中实现,而且可以在将这些测试过渡到制造环境的过程中实现。

特点

- 高速偏振扰偏器,速率可编程(从 1.00 rad/秒到 3.00 Mrad/秒 )

- 可在 C/L、O 和全波段中工作,插入损耗小于 3dB

- 设计为可进行统一扰偏,与输入偏振状态无关

- 提供了 6 种先进的扰偏模式,包括瑞利、随机和环形

- 利用拥有专利的 SOP 反馈选件,能够实现偏振稳定化和状态恢复

- 通过传统的波片手动控制偏振

应用

- 光电子通信测试自动化

- 100G+ 相干接口测试

- 用于损耗、增益和 PDL 最小值/最大值测量的暂时性消偏器

- 目标 SOP 的稳定化和跟踪

Care Support Plans

| Product Group | Recommended Plan | Bronze | Silver | Maxcare | |

|---|---|---|---|---|---|

| MAP (Mainframe/Module) | Bronze-3 | Does the product require calibration? Common questions or issues |

-

VIAVI Care Support for Existing Equipment

FleetCare plans can be customized to include any service entitlements on your fleet of existing equipment. Please fill out a Service Contracts form for a quote.

- Any collection instruments with a single coterminous renewal date

- Each contract is customized with any number of annual terms required by the customer

- Onsite Calibration, Training, Field Application Engineer days can be added

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards