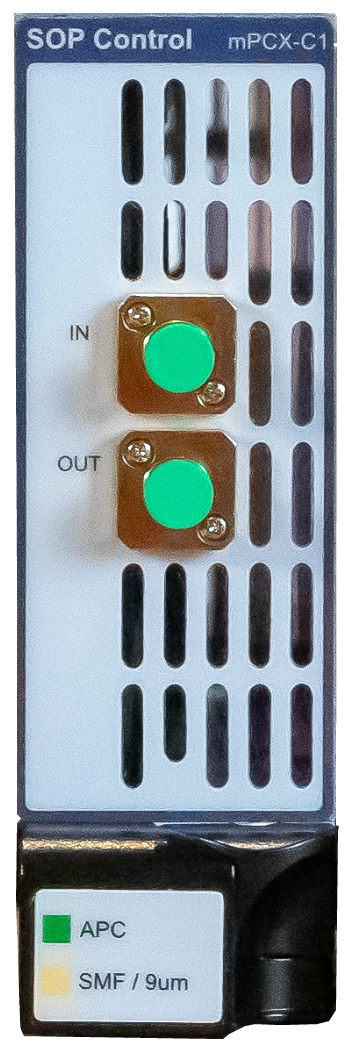

マルチアプリケーションプラットフォーム(MAP)用の偏波制御モジュール(mPCX-C1)は、単一スロットの高速偏波スクランブラー、コントローラー、スタビライザです。 ニオブ酸リチウムベースの電気光学波長板は、最も要求の厳しい偏波管理アプリケーションに必要な応答時間を備えています。 コヒーレント変調フォーマットと偏波多重システムの出現で、これらの信号の偏波状態がシングルモードファイバーと相互作用する様子を理解することの重要性が高まっています。 MPCX-C1 は、実験室でこれらのテストに対応できるようにするばかりでなく、製造環境においてもこれらテスト実施できます。

特長

- 高速な偏波スクランブラー、毎秒1.00rad~3.00Mradの範囲でレートをプログラム可能

- C/L、O、全バンド運用時の挿入損失は 3dB 未満

- 偏波の入力状態に依存しない、独立した一様なスクランブル設計仕様

- Rayleigh、Random、Ring など 6 通りの先進スクランブルモード

- 独自の SOP フィードバックオプションによる偏波の安定化と状態復帰機能

- クラシック波長板による偏波の手動制御

アプリケーション

- 光通信テストの自動化

- 100G+ コヒーレントインターフェイステスト

- テンポラルデポラライザによる損失、利得、および PDL 最小値/最大値測定

- 目標 SOP の安定化とトラッキング

Care Support Plans

| Product Group | Recommended Plan | Bronze | Silver | Maxcare | |

|---|---|---|---|---|---|

| MAP (Mainframe/Module) | Bronze-3 | Does the product require calibration? Common questions or issues |

-

VIAVI Care Support for Existing Equipment

FleetCare plans can be customized to include any service entitlements on your fleet of existing equipment. Please fill out a Service Contracts form for a quote.

- Any collection instruments with a single coterminous renewal date

- Each contract is customized with any number of annual terms required by the customer

- Onsite Calibration, Training, Field Application Engineer days can be added

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards