The Multiple Application Platform (MAP) Fabry-Perot Laser Source (mFPL-A1) is optimized for the industry-leading VIAVI MAP-200 platform. Based on the previous-generation Multiple Application Platform (MAP), the MAP-200 is the first photonic layer lab and manufacturing platform that is LAN Extensions for Instrumentation (LXI)-compliant by conforming to the required physical attributes, Ethernet connectivity, and interchangeable virtual instrument (IVI) drivers. The MAP-200 platform is optimized for density and maximum configurability to meet specific application requirements in the smallest possible foot print.

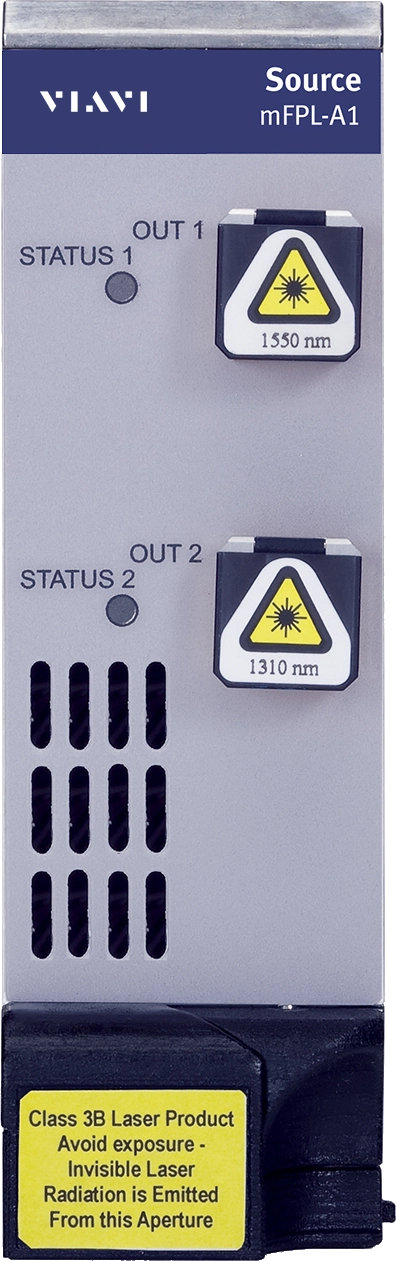

The mFPL-A1 consists of a Fabry-Perot laser diode combined with a high performance laser driver circuitry for optimal wavelength and power stability. It features internal modulation capabilities and variable power control. Cassettes can be configured with two independent sources for maximum instrumentation density.

Key Features

- Dual independent sources available in a single cassette

- Single-mode (SM)/Multimode (MM) output

- Internal modulation

- Can be automated when used with MAP-200 LXI-compliant interfaces and IVI drivers

Hojas de especificaciones

-

VIAVI Care Support

Services Bronze Silver MaxCare Imagen Imagen

Imagen Imagen

Imagen

Technical Assistance Premium Premium Premium Factory Repair Priority Service Self-paced Training Factory Calibration Express Loaner * 5-year plans only; if applicable

-

VIAVI Care Support for Existing Equipment

FleetCare plans can be customized to include any service entitlements on your fleet of existing equipment. Please fill out a Service Contracts form for a quote.

- Any collection instruments with a single coterminous renewal date

- Each contract is customized with any number of annual terms required by the customer

- Onsite Calibration, Training, Field Application Engineer days can be added

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards

Asistencia en cada paso

Proporcionamos soporte técnico, servicios, una formación completa y los recursos que necesita. Todo ello forma parte de lo que hacemos con el fin de maximizar el valor de su inversión en VIAVI.

Déjenos ayudarle

Estamos a su disposición para ayudarle a avanzar.