对数据中心中存储的数据的完整性进行保护非常重要。正是因为知道这一点的重要性,大多数数据中心运营商都会通过高性能网络链路将数据备份到其他数据中心。为了保持这些连接的性能,并且为了验证 SLA,数据中心必须要经常对线速率高达 100G 及以上的以太网以及 OTN、CWDM 或 DWDM 环路执行比特误码率 (BER) 测试。问题在于,在许多数据中心中,能够运行测试以确保连接质量的技术人员寥寥无几。

MAP 2100 旨在使数据中心运营商能够在无人值守的数据中心安全地运行高性能比特误码率测试。

典型用例

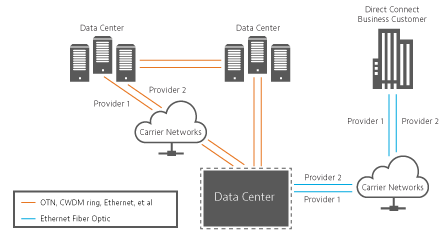

- 局到局(数据中心互连)

- 场景:需要对站点间的网络进行测试,但任何一个站点都没有技术人员能够通过便携手持式测试仪

- 运行测试

- 解决方案:在两个站点均部署 MAP-2100,通过安全通信以远程方式运行测试

- 加密强度高达 256 位

- 通过 SSH(端口 )转发所有管理连接,提高安全性

- 手动到局

- 场景:两个站点,但只有一个站点配备便携式测试仪和技术人员(通常为两人)

- 测试

- 解决方案:在一个站点上使用便携式 MTS-5800,在另一个站点上依靠机架安装式 MAP-2100 进行测试

- 只需一名技术人员便可运行测试,从而节省费用和人工

- 使用 Smart Access Anywhere,任一测试设备都可控制另一台设备

- 跨海线路

- 场景:跨大陆的多个机房,既有陆地部分,又有水下部分。需要对工厂之间的网络进行测试,确保网络功能正常。

- 解决方案:在多个站点部署 MAP-2100 设备,只需技术人员进行最少干预即可执行高效、高容量测试。

- 基于软件的测试和测量 (Fusion)

- 场景:混和物理和虚拟电路的“混合”网络有多个测试点(便携、机架安装和虚拟);需要通过北向 Netconf/YANG 接口对这些测试点进行集中控制

- 解决方案:VIAVI Fusion 通过符合 LMAP 标准的架构在多个物理和虚拟测试点上运行标准化 BERT 和性能监控 (TWAMP)。

特点:

- 针对远程无人干预测试优化,采用机架安装式设计,并具备远程管理功能

- 以太网测试,1G 至 100G 线速率(10G、25G、40G、100G)

- 完全支持包括以太网、OTN、SONET/SDH、PDH、光纤通道(最高 32G)、CPRI 在内的协议

应用:

- 对连接数据中心或中心局/头端的网络链路的传输质量进行远程测试

- 数据中心及核心网络/城域网中 10 Mbps 至 100G 接口的融合以太网/IP 网络测试及故障排查

- OTN 以及传统 SONET/SDH 和 DSx/PDH 网络的安装和维护

主要特点:

- 机架安装,1U 19 英寸宽,提供 21 英寸套件

- 业界最快的 RFC 2544 和 Y.1564 SAMComplete™ 以太网服务激活测试(包括纳秒级精度延迟测量)。还支持 RFC 6349 TrueSpeed

- 通过现场优化的光学器件自检确保 SFP+/SFP28、QSFP+/QSFP28 和 CFP4 模块无误运行

- 借助 OTN 检查工作流自动化脚本测试 OTN 服务激活

- 使用内置的 GNSS 测试同步和定时

- 至32G 的光纤通道

- SONET SDH/PDH

- 借助内置 GNSS 测试以太网单向延迟

Part of The VIAVI Remote PHY Solution

This product is part of the comprehensive VIAVI Remote PHY turn-up and maintenance solution enabling seamless transitions from legacy to distributed access architectures.

软件下载

视频

快速参考

- Quick Tech Tip: Getting the Most Out of 16 QAM

- T-BERD/MTS-5800 - 5GNR Discovery

- T-BERD/MTS-5800 - Assigning Floating Options in Stratasync

- T-BERD/MTS-5800 - CPRI Check, Dark Fiber and WDM Loopback Testing

- T-BERD/MTS-5800 - CPRI Check, RRU Connectivity Testing

- T-BERD/MTS-5800 - CPRI Check, RRU Testing with Nokia/ALU BBU Emulation and RF over CPRI Spectrum Analysis

- T-BERD/MTS-5800 - CPRI Check, SFP/SFP+ Loopback Testing

- T-BERD/MTS-5800 - DS1 PPP Ping Testing (T1 MPLS)

- T-BERD/MTS-5800 - DS3 Bit Error Rate Testing (BERT)

- T-BERD/MTS-5800 - Enabling the GNSS/GPS Receiver for Sky Plot, One-Way Delay, and Sync Measurements

- T-BERD/MTS-5800 - Ethernet 4x10GigE Link Aggregation Loopback

- T-BERD/MTS-5800 - Ethernet 4x10GigE LInk Aggregation Traffic Generation

- T-BERD/MTS-5800 - Ethernet 4x10GigE LInk Aggregation Y,1564 test

- T-BERD/MTS-5800 - Ethernet AOC/DAC Breakout Cable Testing

- T-BERD/MTS-5800 - Ethernet AOC/DAC Cable Testing

- T-BERD/MTS-5800 - Ethernet Bit Error Rate Testing (BERT)

- T-BERD/MTS-5800 - Ethernet J-Profiler VLAN Analysis

- T-BERD/MTS-5800 - Ethernet Layer 2 Traffic Generation

- T-BERD/MTS-5800 - Ethernet Layer 2 Traffic Loopback

- T-BERD/MTS-5800 - Ethernet Layer 3 IPv4 Ping Test

- T-BERD/MTS-5800 - Ethernet Layer 3 Multicast Analysis

- T-BERD/MTS-5800 - Ethernet Layer 3 Multicast Traffic

- T-BERD/MTS-5800 - Ethernet Layer 3 Traffic Generation

- T-BERD/MTS-5800 - Ethernet Layer 3 Traffic Loopback

- T-BERD/MTS-5800 - Ethernet Optics Self-Test

- T-BERD/MTS-5800 - Ethernet Packet Capture from an Optical TAP, v28.0

- T-BERD/MTS-5800 - Ethernet Packet Capture from SPAN port, v28.0

- T-BERD/MTS-5800 - Ethernet Packet Capture in Copper 10-100-1000 Dual Through Mode v28.0

- T-BERD/MTS-5800 - Ethernet Packet Capture in Optical SFP Through Mode v29.0

- T-BERD/MTS-5800 - Ethernet RFC 2544 Layer 2 Traffic

- T-BERD/MTS-5800 - Ethernet RFC 2544 Layer 3 Traffic

- T-BERD/MTS-5800 - Ethernet RFC 6349 TrueSpeed - Local Unit

- T-BERD/MTS-5800 - Ethernet RFC 6349 TrueSpeed - Remote Unit

- T-BERD/MTS-5800 - Ethernet RFC 6349 TrueSpeed Test to Fusion VNF

- T-BERD/MTS-5800 - Ethernet Voice over IP (VOIP) SIP Trunk Testing

- T-BERD/MTS-5800 - Ethernet Y.1564 L2 Multiple Streams

- T-BERD/MTS-5800 - Ethernet Y.1564 L2 Traffic

- T-BERD/MTS-5800 - Exporting System Information and Software Option Inventory

- T-BERD/MTS-5800 - Fiber Channel Layer 2 Traffic

- T-BERD/MTS-5800 - Installing New Options Using an Option Key

- T-BERD/MTS-5800 - ISDN Primary Rate Interface (PRI) Testing

- T-BERD/MTS-5800 - Monitoring DS1 Signals at a Digital Cross Connect Panel

- T-BERD/MTS-5800 - One Way Delay (OWD) Measurement

- T-BERD/MTS-5800 - OTN Check Test

- T-BERD/MTS-5800 - Remote Operation and File Transfer with Smart Access Anywhere

- T-BERD/MTS-5800 - SONET Bit Error Rate Testing (BERT)

- T-BERD/MTS-5800 - StrataSync

- T-BERD/MTS-5800 - T1 Bit Error Rate Testing (BERT)

- T-BERD/MTS-5800 - Tuning SFP+ Transceiver

- T-BERD/MTS-5800 - Updating Software via Internet

- T-BERD/MTS-5800 – Ethernet Layer 4 TCP WireSpeed Throughput Test to an iPERFv3 Server

- T-BERD/MTS-5800 – Updating Software with a USB Flash Drive

软件和固件版本

Care Support Plans

| Product Group | Recommended Plan | Bronze | Silver | Maxcare | |

|---|---|---|---|---|---|

| MAP (Mainframe/Module) | Bronze-3 | Does the product require calibration? Common questions or issues |

-

VIAVI Care Support for Existing Equipment

FleetCare plans can be customized to include any service entitlements on your fleet of existing equipment. Please fill out a Service Contracts form for a quote.

- Any collection instruments with a single coterminous renewal date

- Each contract is customized with any number of annual terms required by the customer

- Onsite Calibration, Training, Field Application Engineer days can be added

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards