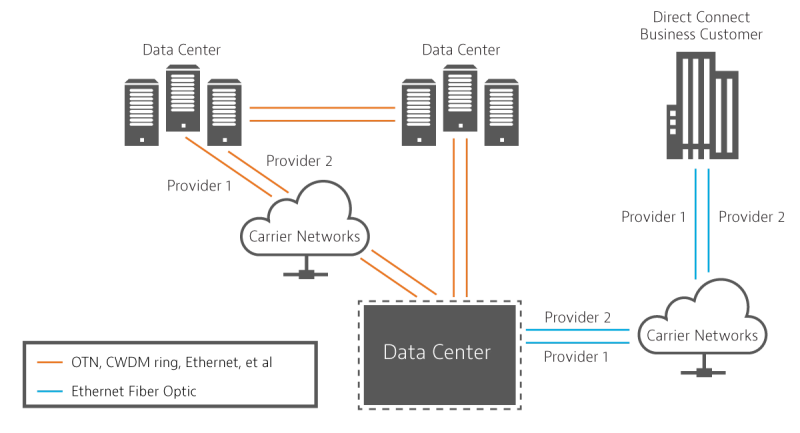

Securing the integrity of data stored in data centers is so important that most data center operators back up data to other data centers via high-performance network links. To maintain the performance of those connections and to verify SLAs, a data center must frequently perform bit-error-rate (BER) tests on Ethernet line rates up to 100G and beyond, as well as OTN, CWDM, or DWDM circuits. The problem is that many data centers have very few, if any, technicians to run tests ensuring the quality of connections.

The MAP 2100 was designed to enable data center operators and network service providers to securely run high-performance bit error rate tests to unmanned locations.

Key Use Cases

- Office-to-office (data center interconnect)

- Scenario: Need to test the network between sites, but neither site has a technician to run tests via portable,

- hand-held testers

- Solution: MAP-2100 at both sites, run tests remotely via secure communications

- Encryption up to 256 bits

- Additional security by forward all management connectivity through SSH (port )

- Manual-to-office

- Scenario: Two sites, but only one with a portable tester and a technician present – typically, this is a two-person

- Test

- Solution: Use a portable T-BERD/MTS-5800 on one site and test against a rack-mounted MAP-2100 in the other

- Only one technician is required to run the test saving expense, man hours

- Either test unit can be controlled by the other using Smart Access Anywhere

- Submarine

- Scenario: Multiple plants with a mix of terrestrial, dry, and wet. Need to test between plants to ensure the network is performing to capacity.

- Solution: Deploy MAP-2100 units at multiple sites to provide efficient, high-capacity testing with minimal technician intervention.

- Software-based Test and Measurement (Fusion)

- Scenario: A “hybrid” network with a mix of physical and virtual circuits has multiple test points; portable, rack-mounted, and virtual, with a need to control them all from a central location via a northbound Netconf/YANG interface

- Solution: VIAVI Fusion runs standardized BERT and performance monitoring (TWAMP) over multiple test points, both physical and virtual, via an LMAP-compliant architecture.

Highlights:

- Optimized for remote, un-manned testing with a rack-mounted design and remote management functionality

- Ethernet testing, 1G through 100G line rates (10G, 25G, 40G, 100G)

- Complete support of protocols including Ethernet, OTN, SONET/SDH, PDH, Fiber Channel up to 32G, CPRI

Applications:

- Remotely test the transmission quality of the network links connecting data centers or central offices/head-ends

- Converged Ethernet/IP network testing and troubleshooting at 10 Mbps to 100G interfaces for data centers and core / metro networks

- Installation and maintenance of OTN and legacy SONET/SDH and DSx/PDH networks

- Data service turn-up, performance validation and monitoring for Submarine Cable Networks

Key Features:

- Rack mounted, 1U 19” wide, kits available for 21”

- The industry’s fastest RFC 2544 and Y.1564 SAMComplete™ Ethernet service activation test including nanosecond accurate latency measurements. Also supports RFC 6349 TrueSpeed

- Ensures SFP+/SFP28, QSFP+/QSFP28, and CFP4 modules run error-free with the field optimized Optics Self-Test

- Test OTN service activation with the OTN Check workflow automated script

- Test synchronization and timing using built-in GNSS

- Fiber Channel up to 32G

- SONET SDH/PDH

- Ethernet One-Way Delay with built-in GNSS

Part of The VIAVI Remote PHY Solution

This product is part of the comprehensive VIAVI Remote PHY turn-up and maintenance solution enabling seamless transitions from legacy to distributed access architectures.

Application Notes

Brochures

Case Studies

Quick References

- Quick Tech Tip: Getting the Most Out of 16 QAM

- T-BERD/MTS-5800 - 5GNR Discovery

- T-BERD/MTS-5800 - Assigning Floating Options in Stratasync

- T-BERD/MTS-5800 - CPRI Check, Dark Fiber and WDM Loopback Testing

- T-BERD/MTS-5800 - CPRI Check, RRU Connectivity Testing

- T-BERD/MTS-5800 - CPRI Check, RRU Testing with Nokia/ALU BBU Emulation and RF over CPRI Spectrum Analysis

- T-BERD/MTS-5800 - CPRI Check, SFP/SFP+ Loopback Testing

- T-BERD/MTS-5800 - DS1 PPP Ping Testing (T1 MPLS)

- T-BERD/MTS-5800 - DS3 Bit Error Rate Testing (BERT)

- T-BERD/MTS-5800 - Enabling the GNSS/GPS Receiver for Sky Plot, One-Way Delay, and Sync Measurements

- T-BERD/MTS-5800 - Ethernet 4x10GigE Link Aggregation Loopback

- T-BERD/MTS-5800 - Ethernet 4x10GigE LInk Aggregation Traffic Generation

- T-BERD/MTS-5800 - Ethernet 4x10GigE LInk Aggregation Y,1564 test

- T-BERD/MTS-5800 - Ethernet AOC/DAC Breakout Cable Testing

- T-BERD/MTS-5800 - Ethernet AOC/DAC Cable Testing

- T-BERD/MTS-5800 - Ethernet Bit Error Rate Testing (BERT)

- T-BERD/MTS-5800 - Ethernet J-Profiler VLAN Analysis

- T-BERD/MTS-5800 - Ethernet Layer 2 Traffic Generation

- T-BERD/MTS-5800 - Ethernet Layer 2 Traffic Loopback

- T-BERD/MTS-5800 - Ethernet Layer 3 IPv4 Ping Test

- T-BERD/MTS-5800 - Ethernet Layer 3 Multicast Analysis

- T-BERD/MTS-5800 - Ethernet Layer 3 Multicast Traffic

- T-BERD/MTS-5800 - Ethernet Layer 3 Traffic Generation

- T-BERD/MTS-5800 - Ethernet Layer 3 Traffic Loopback

- T-BERD/MTS-5800 - Ethernet Optics Self-Test

- T-BERD/MTS-5800 - Ethernet Packet Capture from an Optical TAP, v28.0

- T-BERD/MTS-5800 - Ethernet Packet Capture from SPAN port, v28.0

- T-BERD/MTS-5800 - Ethernet Packet Capture in Copper 10-100-1000 Dual Through Mode v28.0

- T-BERD/MTS-5800 - Ethernet Packet Capture in Optical SFP Through Mode v29.0

- T-BERD/MTS-5800 - Ethernet RFC 2544 Layer 2 Traffic

- T-BERD/MTS-5800 - Ethernet RFC 2544 Layer 3 Traffic

- T-BERD/MTS-5800 - Ethernet RFC 6349 TrueSpeed - Local Unit

- T-BERD/MTS-5800 - Ethernet RFC 6349 TrueSpeed - Remote Unit

- T-BERD/MTS-5800 - Ethernet RFC 6349 TrueSpeed Test to Fusion VNF

- T-BERD/MTS-5800 - Ethernet Voice over IP (VOIP) SIP Trunk Testing

- T-BERD/MTS-5800 - Ethernet Y.1564 L2 Multiple Streams

- T-BERD/MTS-5800 - Ethernet Y.1564 L2 Traffic

- T-BERD/MTS-5800 - Exporting System Information and Software Option Inventory

- T-BERD/MTS-5800 - Fiber Channel Layer 2 Traffic

- T-BERD/MTS-5800 - Installing New Options Using an Option Key

- T-BERD/MTS-5800 - ISDN Primary Rate Interface (PRI) Testing

- T-BERD/MTS-5800 - Monitoring DS1 Signals at a Digital Cross Connect Panel

- T-BERD/MTS-5800 - One Way Delay (OWD) Measurement

- T-BERD/MTS-5800 - OTN Check Test

- T-BERD/MTS-5800 - Remote Operation and File Transfer with Smart Access Anywhere

- T-BERD/MTS-5800 - SONET Bit Error Rate Testing (BERT)

- T-BERD/MTS-5800 - StrataSync

- T-BERD/MTS-5800 - T1 Bit Error Rate Testing (BERT)

- T-BERD/MTS-5800 - Tuning SFP+ Transceiver

- T-BERD/MTS-5800 - Updating Software via Internet

- T-BERD/MTS-5800 – Ethernet Layer 4 TCP WireSpeed Throughput Test to an iPERFv3 Server

- T-BERD/MTS-5800 – Updating Software with a USB Flash Drive

Services

Software & Firmware Releases

Software Download

Video

White Papers & Books

Care Support Plans

| Product Group | Recommended Plan | Bronze | Silver | Maxcare | |

|---|---|---|---|---|---|

| MAP (Mainframe/Module) | Bronze-3 | Does the product require calibration? Common questions or issues |

-

VIAVI Care Support

Services Bronze Silver MaxCare Image Image

Image Image

Image

Technical Assistance Premium Premium Premium Factory Repair Priority Service Self-paced Training Factory Calibration Express Loaner * 5-year plans only; if applicable

-

VIAVI Care Support for Existing Equipment

FleetCare plans can be customized to include any service entitlements on your fleet of existing equipment. Please fill out a Service Contracts form for a quote.

- Any collection instruments with a single coterminous renewal date

- Each contract is customized with any number of annual terms required by the customer

- Onsite Calibration, Training, Field Application Engineer days can be added

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards

Related Products

Support at Every Step

We provide support, services, comprehensive training and the resources you need. It’s all part of what we do to maximize the value of your VIAVI investment.

Let Us Help

We’re here to help you get ahead.