MPO Testing

Industry leading, award winning, purpose-built MPO Test Solutions

VIAVI delivers the industry’s most complete portfolio of test solutions for MPO connectivity. From automated fiber end-face inspection, to length/loss measurements and OTDR testing, testing MPO with VIAVI solutions equip technicians with the ability to ensure network performance without the hassles that come with legacy tools.

Продукты

-

INX 700 Probe Microscope

Automated single and multifiber connector inspection and the industry’s first AI-enhanced image analysis

-

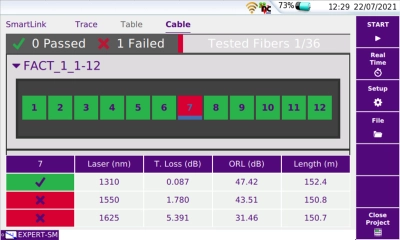

SmartClass Fiber MPOLx — наборы для тестирования оптических потерь многоволоконных кабелей

VIAVI Solutions SmartClass Fiber MPOLx — первый в отрасли специализированный набор для тестирования оптических...

-

FiberComplete PRO

Bidirectional IL/ORL and OTDR fiber acceptance testing done with just one fiber connection and a single button press...

-

Коммутаторы на основе многоволоконного кабеля с MPO-разъемом для полевых измерительных приборов

Решения с коммутаторами высокой емкости (от 12 до 192 портов) позволяют упростить и автоматизировать получение...

-

Приложения Smart Link Mapper (SLM) для рефлектометрии

Представление событий опторефлектометрии в виде значков и немедленное отображение результатов «прошел/не прошел»...

-

FVAM Series Benchtop Microscopes

"All-in-one" benchtop inspection and analysis solution for multifiber connectors such as MPO and pluggable...

MPO Migration

As fiber networks continue to migrate more towards MPO connectivity, technicians are finding that their legacy test tools are no longer sufficient for the job. Using tools that were not designed for MPO has introduced challenges ranging from taking extra steps during inspection and testing to needing additional equipment to perform tests. All this adds up to extended test times and frustration.

VIAVI Solutions has developed an extensive portfolio of industry leading, award winning test solutions that are purpose built for testing MPO, giving technicians with the ability to ensure the MPO performance in any fiber network. Not only do our solutions help you test efficiently, they also drive you to test correctly, eliminating unnecessary steps and driving best practice test methods.

MPO Test Solutions from VIAVI

VIAVI is addressing the evolution in MPO connector testing with four new–and fast–solutions:

Get help from the MPO experts at VIAVI today!

Are you ready to take the next step with one of our MPO test products or solutions? Or want to ask a question about MPO testing? Complete one of the following forms to continue:

White Papers и книги

Поддержка на каждом этапе работы

Мы оказываем техническую поддержку, предоставляем услуги, программы обучения и все необходимые материалы. Наша деятельность направлена на максимальное повышение отдачи от ваших капиталовложений в систему VIAVI.

Спросите у специалиста

Обращайтесь к нам для получения дополнительной информации и ценовых предложений. У нас есть специалисты, готовые дать правильный ответ на любой ваш вопрос.