マルチアプリケーションプラットフォーム(MAP)偏波コントローラー(mPCS-A1)は、業界トップの VIAVI MAP-200 プラットフォーム向けに最適化されています。前世代のマルチアプリケーションプラットフォーム(MAP)に基づいた MAP-200 は、必要な物理属性、イーサネット接続、および交換可能な仮想計測器(IVI)ドライバーに適合することにより、計測器用 LAN 拡張機能(LXI)に準拠した最初のフォトニックレイヤーのラボおよび製造用プラットフォームです。MAP-200 プラットフォームは、最小限の設置面積で特定のアプリケーション要件を満たすために、密度と最大限の設定変更の可能性が得られるように最適化されています。

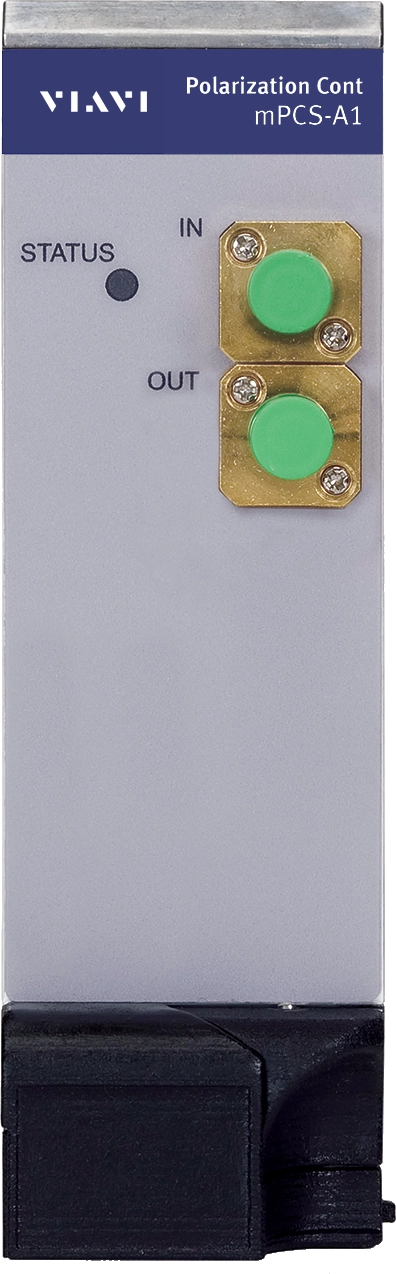

mPCS-A1 は、どのような偏光状態をも作成できる効率的かつ正確な方法を提供します。また、偏光状態アナライザの一部としても使用できます。mPCS-A1 は、高消光比偏光子、1/4 波長板、1/2 波長板の 3 つの回転素子で構成されています。コントローラーの設定は、シングルモード(SM)または偏波保持ファイバー(PMF)入力で行うことができます。

偏波コントローラーを他の測定器と組み合わせて、エルビウム添加ファイバー増幅器(EDFA)や受動素子のテストセットなどの測定テストシステムを完成できます。

主な特徴

- 完全な偏光制御

- IEEE 規格 802.3aeTM 10 GbE テスト要件を満たすように設計

- 高速偏波依存損失(PDL)測定(4 状態のミュラー法)を実行するように設計

- コンパクトなシングル幅カセット

- 非常に高い角度精度と絶対高速軸アライメント精度

- MAP-200 LXI 準拠のインターフェイスおよび IVI ドライバーと併用すると自動化が可能

印刷物

アプリケーションノート

Care Support Plans

| Product Group | Recommended Plan | Bronze | Silver | Maxcare | |

|---|---|---|---|---|---|

| MAP (Mainframe/Module) | Bronze-3 | Does the product require calibration? Common questions or issues |

-

VIAVI Care Support for Existing Equipment

FleetCare plans can be customized to include any service entitlements on your fleet of existing equipment. Please fill out a Service Contracts form for a quote.

- Any collection instruments with a single coterminous renewal date

- Each contract is customized with any number of annual terms required by the customer

- Onsite Calibration, Training, Field Application Engineer days can be added

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards