What is Fiber Testing?

Learn all about fiber testing including testing fiber for optical loss and optical speed as well as fiber testing best practices and procedures.

Fiber testing encompasses the processes, tools, and standards used to test fiber optic components, fiber links, and deployed fiber networks. This includes optical and mechanical testing of discreet elements and comprehensive transmission tests to verify the integrity of complete fiber network installations.

Fiber optics have emerged as the world’s leading communication transport medium based on 3 distinct advantages over copper-based infrastructure: reduced cost of operation in terms of power and maintenance, reliability (fiber optic cables are immune to electromagnetic and radio frequency interference), and superior bandwidth/transmission speeds. The increasing diversity of fiber optic applications and point-to-point (PTP) and point-to-multi-point (PTMP) architectures highlights the need for technician training and versatile, user-friendly test solutions.

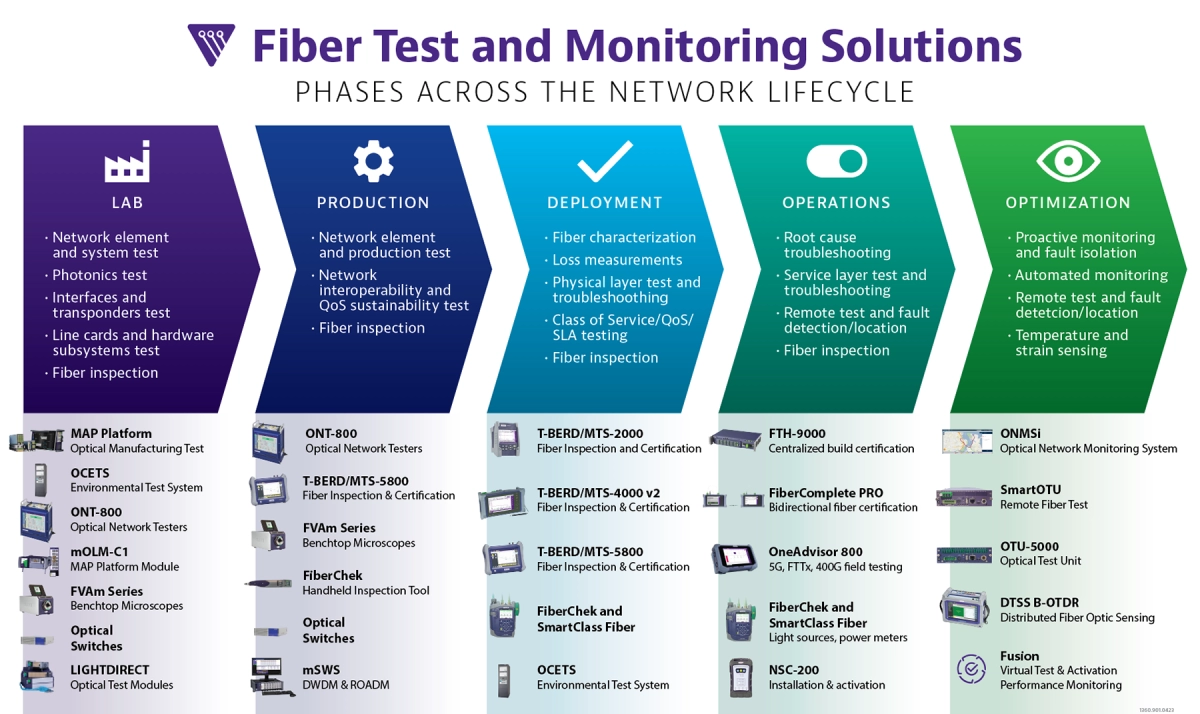

Since their inception in the 1970s, fiber optic networks have continually evolved and expanded. The emergence of 5G, submarine networks, data center, and FTTx (Fiber to the X) have highlighted the importance of a robust fiber infrastructure and the need for reliable fiber testing and monitoring. VIAVI offers an unmatched heritage of technical proficiency, reliability, and collaboration for nearly 100 years that has yielded the industry’s premier fiber testing solutions.

With the size and complexity of today’s fiber networks, productivity is no longer an option. Efficiency must begin in the lab and extend throughout construction, installation, and maintenance. VIAVI offers a fully integrated portfolio of cloud-enabled fiber test instruments, software, and services that are flexible and interoperable. The next generation of fiber optic test tools is now faster, easier to use, and more powerful than ever before.

Essential Resources:

Fiber optic industry standards have been developed over the years to certify fiber network components and installations prior to use. As deployments multiply, adherence to national and international standards is necessary to maintain consistency, interoperability, and performance. All fiber network operators and their customers benefit greatly by deploying consistent, standards-based fiber testing to enable success throughout the network lifecycle, from fiber construction and customer service activation, to assurance monitoring, network maintenance, and upgrade.

Multiple standards bodies and working groups focus on various geographical regions, fiber network types and applications. As an active participant in standard development and review, VIAVI works side by side with the leading standards bodies to facilitate the next generation of fiber testing products and services.

The International Electrotechnical Commission (IEC) is a global standards organization that prepares and publishes international standards for electrical, electronic, and related technologies. Formed in 1906, the IEC has established multiple standards and technical committees related to fiber optics. This includes recognized international standards for fiber geometry, attenuation, macro bending loss, and chromatic dispersion.

Within the United States, the Telecommunications Industries Association (TIA) and Electronic Industries Alliance (EIA) produce important national standards for many telecommunications applications, including testing fiber networks and equipment.

TIA standards include the widely used Tier 1 fiber installation certification requirements. While Tier 1 certification is limited to length, polarity, and overall link loss, Tier 2 testing is used to produce more descriptive test results, including loss event location and magnitude, using OTDR fiber test equipment.

The Internet Engineering Task Force (IETF) is an open organization focused exclusively on Internet standards and policy. As fiber optics continue to provide a fundamental building block of internet architecture, the IETF cooperates with the International Electrotechnical Commission (IEC), International Standards Organization (ISO), and other important working groups to standardize and secure fiber networks as an Internet pathway.

The Fiber Optic Association (FOA) is an international non-profit educational association and certifying body that promotes professionalism in fiber optics through education, certification, and standards. A network of over 200 FOA schools provide a high level of training for fiber techs all around the world. Industry-recognized FOA certification is available for fiber installation, fiber applications, and fiber optic network design.

In response to the cost and complexity of many existing fiber optic standards, the FOA has also created its own standards for many widely used fiber tests and topics. Standard FOA-1 covers loss testing for installed single-mode and multimode fiber optic links, while FOA-2 is specific to single-ended loss testing methods. FOA-4 covers basic equipment setup and test parameters for OTDR testing.

The Institute of Electrical and Electronic Engineers (IEEE) is the world’s largest technical professional organization, with over 400,000 members spanning electrical engineering, computer science, electronics, and telecommunications. The organization was formed through an amalgamation of the American Institute of Electrical Engineers and the Institute of Radio Engineers. The IEEE maintains a portfolio of over 1000 standards spanning a wide variety of disciplines.

Ethernet physical and data-link layer requirements are defined by the IEEE 802.3 family of standards. The 802.3cp standard has recently been amended to account for high speed, bidirectional data transmission over single-mode fiber, and specifies a bit error rate (BER) of ≤10-12 at the service interface. The 802.3ct standard addresses the unique requirements of Ethernet-based long-distance transmission using dense wave division multiplexing (DWDM).

Fiber optic networks offer unprecedented speed and bandwidth to meet the ever-increasing demand for faster communication networks. The majority of worldwide data transfers now depend on fiber optics continually for reliable high-speed data transmission.

Although one positive attribute of fiber optic cable is low power loss over long distances, the termination and access points to fiber optic networks are still prone to unforeseen loss events that can disrupt this vital service. Thus, fiber optic testers utilizing a variety of fiber testing methods are essential tools. U.S. and International standards have been established to regulate these fiber testing practices, and an array of versatile fiber optic testers have been developed.

Industry performance standards, service level agreements, and warranty requirements make testing fiber optic networks unavoidable, but there are many other reasons why fiber network performance should be tested and monitored. Ultimately, the goal of testing is to maximize the performance capability of the fiber network asset in terms of bandwidth, reliability, and return on investment.

The market demand for bandwidth has led to an increase in the size and complexity of fiber networks. Passive Optical Network (PON) architecture, DWDM (Dense Wavelength Division Multiplexed), and other innovations such as coherent optics, have introduced more cable segments and additional purpose-built components that can increase the risk of additional insertion losses, even as performance requirements increase and loss budgets decrease. Thorough and accurate fiber testing at all network levels and lifecycle phases can ensure customer satisfaction and competitive edge.

Despite the best intentions of highly trained technicians, the relative delicacy of fibers can be unforgiving when it comes to contamination, macro-bending, and connector damage. Dirty connections remain the number one cause of fiber network failures. Testing the network comprehensively prior to turn-on allows any defects or damage to be detected and repaired proactively. While fiber is very durable once installed, it is glass: At each junction point, sound handling and cleanliness are of utmost importance. Once damaged by break, or dirt that crushes or scratches the glass, it can be difficult to restore that fiber to acceptable condition.

Fiber testing is often thought of as the installation activities that verify a fiber network’s readiness. In reality, fiber optic testing extends from the earliest development of new fiber optic components and systems in the lab, through fiber installation and activation, to the monitoring and troubleshooting that ensure years of reliable fiber performance in the field.

Each new fiber optic component or system begins as a concept in the lab. Testing fiber in this lifecycle phase is necessary for proof of concept and design verification. For fiber, this includes transmission parameters like insertion loss, optical return loss and chromatic dispersion. Newly designed fiber products might also subject to tensile, torsion, and temperature testing.

For all fiber network components, effective lab testing requires accurate fiber network simulation to predict real world issues and verify system performance. Optical network elements like digital coherent optical (DCO) modules can be designed and fully validated in the lab with the VIAVI MAP-300 optical test and measurement system. An industry-leading collection of hot swappable optical test modules is also scalable for manufacturing test applications.

Fiber network manufacturing tests are essential for ensuring the system will function properly before a large investment in installation labor, equipment, and validation is made. Optical loss measurements should be performed by the manufacturer at the component and cable assembly level. Mechanical type fiber testing for important parameters should also be performed.

Custom built cable runs are often pre-terminated to speed installation. The same versatile fiber optic test and inspection equipment used in the field can be utilized to verify production cable quality and establish an optical loss baseline.

Every module, connector, splitter, and transponder in a deployed fiber network should be subject to these same high-quality standards. Scalable, automated manufacturing and environmental test systems provide the efficiency needed to meet the growing production demands on the fiber optic industry.

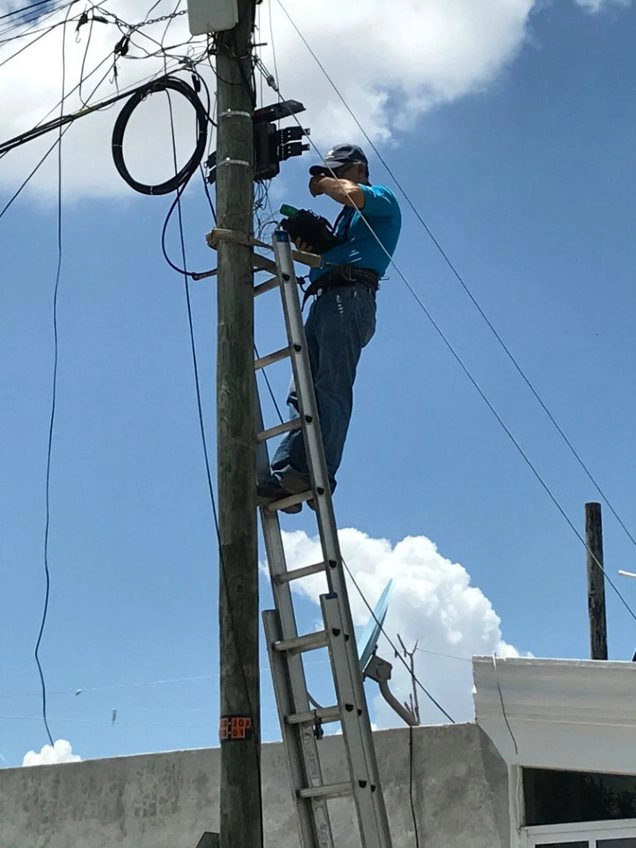

When everything comes together during fiber network installation, the focus is on timely and precise measurement and certification with objective close-out fiber test reporting to provide proof that the network is built as planned to achieve the optimal performance and optical budget margin required for high-speed transmission. It is common to “overbuild” on top of an existing copper network and to reuse or replace existing cabinet, pedestal, and hub/exchange infrastructure. One often finds that above-ground obstacles require some modification to the prior route that is now overlayed with other infrastructure.

Four elements dictate success at deployment:

- Engineering preparation in the form of detailed survey and layouts, loss budgets, and pre-installation fiber route inspection are prerequisites.

- Network elements that are designed for simplified installation and easy connectorization save time and eliminate error in the field.

- Easy to use, repeatable test plan processes and automated reporting/analysis are the second consideration. This is known as test process automation (TPA). The fiber test process should readily compare plan to actual as-built network inventory and performance characteristics, such as distance, optical budget and attenuation of the end-to-end line and each planned event such as the connector or splice.

- A trained staff armed with accurate and calibrated fiber optic test devices or built-in network test with a remote fiber test system (RFTS) is another. It is invaluable to have staff that know how to handle the fiber network elements, document their work, and troubleshoot faults at construction, but the test system used can go a long way to automating the work for the many field technicians it takes to build out a full network.

Construction, installation, and commissioning tests are completed to verify end-to-end fiber link length, loss and optical return loss (ORL), cable, splice, passive optical elements (splitters, MUX/DEMUX) and termination quality (attenuation, location, and reflectance). Insertion loss/ORL, length, polarity, and continuity (also referred as Tier 1 in Enterprise/Structured Cabling environment) and OTDR (Tier 2) fiber testing and fiber characterization require a variety of tools. This includes visual fault locators (VFLs), optical loss test sets (OLTS), optical time domain reflectometers (OTDRs), and remote fiber test systems (RFTS). An RFTS offers OTDR, automated fiber switching capability, and a light source to verify connectivity, continuity, power level, and attenuation of specific events between the transmission element to a given test point.

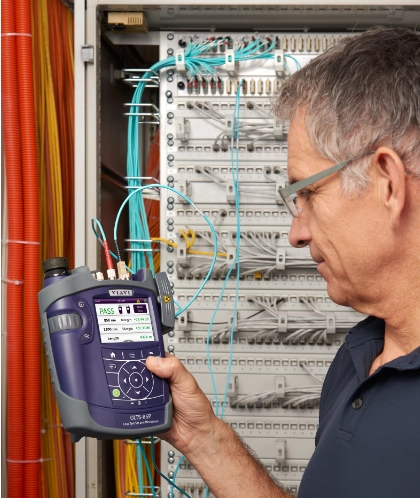

VIAVI test solutions in the SmartClass family feature integrated handheld products capable of performing fiber inspection, Tier 1 certification, and reporting tasks efficiently with a single instrument, while modules for the T-BERD/MTS and OneAdvisor 800 platforms cover tier 2, xWDM, dispersion and other test requirements. The VIAVI ONMSi RFTS is built into the network to perform centralized fiber test across thousands of lines with a central management server that can record all results, schedule automated tests, and send alarms should conditions fail to meet compliance on the network. In this case, the technician can use a web browser on a mobile device or desktop to initiate a test or schedule a routine test across many fibers while carrying a tiny reflector into the field to demarcate the test point and a unique test “fingerprint” for that location. Fiber test equipment cost is reduced, time to test is reduced, and the system can remain in place for the next phase of fiber network operation.

Once the network is operational, customers will subscribe or change their service (also known as an add/drop service event). A pre-activation fiber test can be run using the RFTS to verify the optical budget and service level that can be supported to a PON or PTP network ID location. This prevents the technician from arriving at the customer premise only to find that something upstream is an issue and another appointment is required. Once at the customer premise, the customer service speed can be tested on the customer premise side of the ONT/ONU and bit error tests can be run.

Over 90% of all internet traffic terminates on a wireless client, such as a mobile phone over wireless 4G/5G or a TV over WiFi. Often a customer believes their fiber service performance is the cause of problems, when the real problem lies in the WiFi or 5G RAN network, thus testing is the only way to ensure end-to-end performance.

WiFi and wireless RAN speed and coverage tests can also help qualify a successful service installation and demarcate issues between the wireless termination client experience and the fiber network.

Testing fiber networks does not end with turn-up. Once the network has been activated, fiber monitoring is used to assess ongoing integrity. Monitoring is sometimes performed as a periodic check, although active fiber monitoring (AFM) to continually detect issues or intrusions is the industry best practice. The VIAVI ONMSi and fiber test head family remote fiber test solutions simplify continuous fiber monitoring by enabling remote, automated monitoring with proactive alerts to degradation caused by damage or human mishandling, outages, power loss, or flash power losses that disrupt service.

Roughly 50% of data centers experience a service outage each year and most service customers experience poor speed or quality intermittently each year. An RFTS system, such as ONMSi RFTS, is the first line of defense in protecting the network and the service performance. It will automatically scan to identify and locate faults, alert operators, and assist in demarcation between possible network sections. For example, if the data center network is experiencing an outage, it could be a fiber break or cable disconnect, a power outage, a software failure, or an attack. The RFTS can quickly identify or rule out the fiber break scenario and determine if the power is out. Because physical problems are the most common, the technician needs to rule this out or resolve it before moving up the troubleshooting stack to equipment failures or software issues.

When problems in the network are detected, troubleshooting must pinpoint the root cause quickly. Typical field issues involve outages or service degradations related to compromised cable, connectors, or hardware. OTDR and other fiber optic test tools used during installation and turn-up can also be utilized to effectively troubleshoot these issues and reduce mean time to repair (MTTR). Sixty percent of the time, an average MTTR comprises locating the problem vs. fixing the problem. When the problem can be auto-detected and located, the technical team can be dispatched to fix, not to find, saving hours and often days of time to resolution. That translates to thousands, if not millions in costs averted and revenue lost due to outage.

Testing fiber optic networks is an essential part of fiber optic installation, as well as ongoing maintenance. Following some fundamental fiber testing best practices will lead to safer, more efficient, and more reliable fiber deployments and network activation.

- The importance of cleanliness in fiber installation and testing cannot be overstated. A fiber optic microscope fiber optic microscope can be used as a fiber optic tester to verify the cleanliness of the core and connecting ferrules. Automated inspection tools can be used for common fiber interfaces like simplex (FC, SC, LC, etc..)and MPO. Specialized cleaning materials are recommended for proper cleaning of fiber optic connections. This same attention to cleanliness should be applied to reference cables and test equipment connections.

- When using a VFL (Visual Fault Locator) fiber tester for fault location, eye safety is extremely important. Since a VFL utilizes a high-intensity laser light source, neither the source nor the fiber core illuminated by the VFL should be viewed directly with the naked eye.

- The use of an optical light source and a power meter, or an optical loss test set (OLTS), or a remote fiber test system (RFTS) is considered a good fiber test practice for ensuring that the optical power budget is within design specifications. A calibrated optical light source (OLS) can be used in conjunction with an optical power meter (OPM) to quantify the insertion loss of the link prior to turn-up.

- An OTDR is the recommended fiber optic test tool for detailed baselining and recording of fiber link characteristics.

- The purpose of an OTDR is to detect, find, and measure events at all locations on a fiber link. Location information regarding localized loss and reflective events is generated, providing technicians with a pictorial and permanent record of the fiber’s characteristics.

- When using an OTDR, use launch and receive cables to qualify the front-end and far-end connectors. A launch cable is connected between a tester and the fiber under test, and the receive cable is connected at the far end of the fiber link. It is important to note that the fiber used in the launch and receive cable should match the fiber being tested (type, core size, modal field diameter (MFD), etc.)

- Test process automation (TPA) principles that are effective on the production floor can also be extended to fiber network installation. By minimizing manual test processes and reducing opportunities for errors and training time, certification and turn-up can be completed and documented confidently and predictably.

- Lastly, proper planning and preparation are basic best practices applicable to any organized endeavor, including fiber testing. Assembling and organizing a pre-cleaned, calibrated, and complete test tool kit is essential for carrying out the most effective and accurate fiber optic tests.

Fiber Testing and Fiber Optic Cable Construction

The application of fiber optic communication may seem simple, but fiber optic cable testing requires an understanding of some basic principles that differentiate fiber testing from its analog wire testing predecessor.

An optical fiber is composed of a very thin glass rod, which is surrounded by a plastic protective coating (cladding). Light, which is injected into the core of the glass fiber, will follow the physical path of that fiber due to the total internal reflection of the light between the core and the cladding.

The Three C’s of an Optical Fiber

The basic elements of an optical fiber in terms of fiber testing are sometimes referred to as the “three C’s”:

- Core: The center of the fiber cable, made of specially treated glass or plastic. This is the medium for light transmission throughout the span of the cable, so it must be as pure and clean as possible.

- Cladding: An additional layer made of material similar to the core, but with a lower refractive index to facilitate continuous reflection of the light source back into the core.

- Coating: The outer layer of the cable which wraps, protects, and insulates the core and cladding.

Types of Fiber

Fiber is classified into different types (multimode or single mode) based on the way in which the light travels through it. The fiber type is closely related to the diameter of the core and cladding. Multimode fiber has a larger core diameter that allows multiple modes of light to pass through it simultaneously.

The primary advantages of multimode fiber are the ease of coupling to light sources and to other fibers, lower cost light sources (transmitters), and simplified connectorization and splicing processes. However, its high attenuation (optic loss) and low bandwidth limit the transmission of light over multimode fiber to short distances.

The advantage of single-mode fiber is its higher performance with respect to bandwidth and attenuation.

The small core size of single-mode fiber requires more expensive transmitters and alignment systems to achieve efficient connector coupling. Nonetheless, for high performance systems or for systems that are more than a few kilometers in length, single-mode fiber remains the best option.

To assess the quality of a fiber installation, sign it off as ready for service activation, and ensure reliable on-going operation of a fiber link, some basic fiber test methods and tools should be used.

There are several important things to measure, assess and check:

Fiber End-Face Inspection

When two fibers are mated together, a key requirement is to ensure light passes from fiber to fiber without excessive loss or back reflections. What remains challenging is maintaining a pristine end face. A single particle mated into the core of a fiber can cause significant insertion loss, back reflection, and even equipment damage. Proactive fiber inspection is essential to ensure reliable fiber connections.

Fiber Continuity Test

When you test fiber optic cable networks, a visible laser source connected to one end of the cable can be used to verify the transmission to the opposite end. This type of fiber optic test is only intended to detect gross fiber defects such as breaks. You can also test fiber optic cable continuity to determine whether the right fiber optic cable is connected to the right patch panel location.

A fiber identifier (FI) is a useful handheld fiber test tool that can identify and detect optical signals from the outside at any point along the fiber link. Fiber identifiers can be used to confirm the presence of traffic on a fiber as well as the direction of the transmission.

A visual fault locator (VFL) uses visible spectrum laser light to test fiber continuity as well as detecting fault conditions. The red-light source will be visible through the coating at the location of any fiber breaks, defective splices or macrobends. For fiber runs longer than 5km/3miles or where access to view the fiber is limited, an OTDR can be used as a fiber optic cable tester to pinpoint any continuity issues.

Modern, two-ended fiber solutions, such as OLTS and FiberComplete, can provide automatic continuity validation and polarity in cases of multi-fiber cables.

Optical Loss Measurement

As light traverses a fiber, it decreases in power level. The decrease in power level, also called optical loss, is expressed in Decibels (dB).

Some may ask what the ‘correct method for loss testing is?’. The most accurate way for fiber testers to measure the overall optical loss in a fiber is to inject a known level of light in one end and measure the level of light at the other end, using an OLTS. The difference between source and receive power levels is the loss. Since the optical light source and power meter are connected to opposite ends of the link, access to both ends of the fiber is required for this method.

Optical Power Measurement

A power measurement is a test of the signal strength from the transmitter once a system is live or activated. An optical power meter will display the optical power received on its photodiode and can be connected directly to the optical transmitter’s output or on a fiber cable at the point where the optical receiver would be. Optical power can be measured in “dBm” units (absolute value), where the “m” represents 1 milliwatt and the “dB” (used when a reference level is set) refers to decibels.

Testing Fiber for Optical Loss

When you test fiber optic cables for optical loss, fiber testers will need to connect to a test source to provide an optical light standard, as well as a launch cable to supply a calibrated “0 dB loss” reference. A power meter at the opposite end of the circuit will measure the light source with and without the fiber under test to quantify the loss in dB of the fiber itself.

Other methods for testing fiber optic cable connections include both launch cables and “receive” cables connected to the power meter. This is the standard test for loss in an installed cable plant and includes the loss measurements at both test cable connection ends. For this reason, ensuring all connections are extremely clean is an important aspect of any fiber test.

An Optical Time Domain Reflectometer (OTDR) can also be used as a fiber optic cable tester to test optical loss. Utilizing high intensity laser light emitted at a pre-defined pulse interval through a connecting cable at one end of the fiber optic cable run, the OTDR instrument analyzes the backscatter of light returning to the source location.

This one-ended fiber test method can be used as a fiber optic tester to quantitatively analyze the loss, as well as pinpointing the loss locations during installation, maintenance, and troubleshooting. Mini-OTDR products pack the functionality of a mainframe OTDR device into a handheld fiber test product, and can integrate other capabilities like fiber end inspection, VFL, and power measurement. Learn more about OTDR Testing.

The Origins of Fiber Optic Test

The transmission of an optical signal through a thin glass “fiber” is not a new concept. Over 100 years ago, experiments showed the ability of light to travel through a curved glass substrate and keep most of its original intensity. By the late 1960’s, laser optics, ultra-transparent glass fibers, and digital signaling combined to form the foundation of the fiber optic communication networks that we know today. By the 1990’s, fiber optic networks could already carry up to 100 times more information than traditional cable with electronic amplifiers.

Fiber optics work by converting electronic/binary information into optical signals in the form of digital light pulses. These signals can be transmitted through long fiber optic runs to a receiver at the far end of the line, where the signal is converted back into its original binary form.. To verify and support the integrity of these optical signals throughout long distance runs and complex networks, and keep pace with the increases in bandwidth, fiber testing processes must continually evolve.

The Future of Fiber Optic Test

The potential of fiber as a communication medium seems unlimited, with new breakthroughs and possibilities continually being found. Promising research into technologies like “twisted light” transmission could eventually lead to 100X bandwidth improvement over the same single mode fiber.

This added ability might be needed sooner than expected, with 5G, the IoT (Internet of Things), and artificial intelligence accelerating the already steep year-over-year uptick in consumption. It is no surprise that the fiber optics testing market is expected to grow at a pace of nearly 9% per year for the foreseeable future.

To secure this bright future, continued development of fiber testing is key. Innovations that begin as unproven concepts will eventually move into production and finally become essential elements of fiber networks around the world. By establishing trusted, interoperable testing solutions with a common DNA that binds all testing lifecycle phases together, VIAVI is enabling fiber test and monitoring solutions to keep pace with imagination.

Start fiber testing with VIAVI today!

Are you ready to take the next step with one of our fiber optic testers?

Complete one of the following forms to get going: