Fiber Optic Sensing

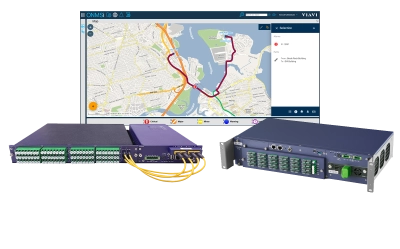

Industry-Leading Modular Fiber Optic Sensors in Portables and Rack-Mounted Options

VIAVI provides Distributed Temperature Sensing (DTS), simultaneous Distributed Temperature and Strain Sensing (DTSS) and Distributed Acoustic Sensing (DAS) solutions to measure optical loss, temperature, temperature and strain, or acoustic vibrations with Brillouin OTDR, Raman OTDR and Rayleigh OTDR on the portable OneAdvisor Fiber Optic Sensing or the rackable Fiber Test Head-Fiber Optic Sensing for remote fiber test and monitoring.

Products

-

FTH-DAS

Protect critical infrastructure from external threats and monitor pipelines for leaks with the most versatile...

-

FTH-DTSS

Monitor temperature and strain of power cables, pipelines and telecom cables with the most versatile optical fiber...

-

FTH-DTS

Monitor temperature of power cables, pipelines and telecom cables with the most versatile optical fiber sensing...

-

ONMSi Remote Fiber Test System (RFTS)

ONMSi Optical Network Management System for Core, Metro, Access and FTTH networks.

-

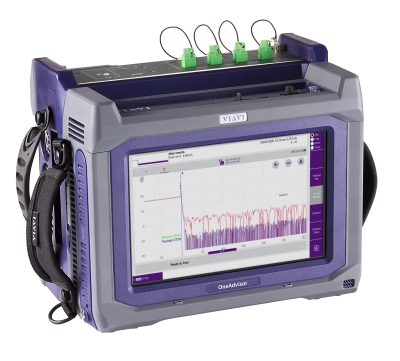

OneAdvisor 800 DTS

Bring distributed temperature sensing technology to the field in a uniquely portable solution. Audit, check and...

-

OneAdvisor 1000 DTSS

Bring distributed temperature and strain sensing technology to the field in a uniquely portable solution. Audit,...

What Type of Fiber Optic Sensing Interrogators Does VIAVI Offer?

The VIAVI fiber sensing portfolio includes:

- DTS (Distributed Temperature Sensing) based on Raman OTDR technology

- DTSS (Distributed Temperature and Strain Sensing) based on Brillouin OTDR technology

- DAS (Distributed Acoustic Sensing) based on coherent Rayleigh backscattering technology

A Fiber Optic Strain Sensor, also known as an optical strain gauge, is an optical fiber used to detect or sense strain through a process known as distributed strain sensing using a specialized OTDR (Optical Time Domain Reflectometer). These sensors are used to measure light changes in the sensor to detect strain on a fiber as areas along the glass fiber stretch producing changes to the glass until it will eventually break under excessive strain. Unlike traditional electrical strain gauges, a passive fiber optic strain sensor does not require constant electrification and is immune to electro-magnetic interference, which is experienced as noise in an electrical strain gauge system. Such noise can render measurements unreadable.

Due to this advantage, they are less expensive to operate and can be used in many harsh physical environments as reliable measurement devices with extraordinary sensitivity to strain change. Detect strain by transmitting a light pulse down the fiber to measure the strain on the glass. These types of measurements can be taken periodically with a portable DTSS (Distributed Temperature and Strain Sensor) OTDR during a field measurement trip or in an automated routine using a permanent, rack-mounted DTSS OTDR. The optical fiber is light weight, inexpensive and thorough coverage can be achieved by attaching the fiber to the device under test in multiple locations.

A fiber optic strain sensor can be used to sense strain in diverse locations such as along a pipeline, on a telecommunications cable, in the earth, along a bridge, or large windmill to secure infrastructure, human life, and prevent environmental damage. All sound measurement processes will establish a baseline of strain upon installation of the fiber optic strain sensor and measure change over time, allowing an automatic alarm to trigger notification of risk should a specified tolerance threshold be breached.

A Fiber Optic Acoustic Sensor is an advanced fiber-optic sensing technology. Unlike traditional sensors that measure at specific points, distributed acoustic sensing (DAS) continuously monitors the entire length of a fiber optic cable. The optical fiber itself becomes a distributed sensing element, allowing it to detect and retrieve information about vibrational disturbances in the area around critical infrastructure over long distances.

Using a portable, such as the VIAVI OneAdvisor 800/1000 platforms with DTS or DTSS capability, a technician can go out into the field and conduct field measurements on fibers. Alternatively, using ONMSi and a rack-mounted Fiber Test Head (FTH) with DTS or DTSS capability a NOC can remotely monitor fibers using periodic traces that are set to alarm if there is a change from the beginning reference trace.

Using a rack mounted solution, such as the VIAVI Fiber Test Head, with acoustic sensing capability (DAS), pipeline owner/operators and power transmission system operators (TSO), etc. can install a real-time monitoring and alarming solution to detect, identify, locate and alert on vibrational disturbances which could represent a threat to assets, such as people, trucks, mechanical or manual digging.

Fiber Optic Sensing is much less expensive and less labor intensive to install and utilize as a data point rich source. The fibers in the cable make up the distributed sensor and this material is inexpensive, lightweight and easy to attach or embed to an object under test.

Fibers are highly-reliable distributed sensors that do not require constant electrical current to produce data, and they are immune to electro-magnetic and radio-frequency interference. Historically, heavy, wired, electrified sensors that are labor intensive to install have been the main data source for obtaining strain or temperature data.

Electro-mechanical sensors can fall off, be intrusive and cost prohibitive and they require a power source. In locations where power is not readily available or, corrosion, vibration or EMI is a problem, they are not practical. Electrical and radio noise ingress or egress distorts their measurement data. A bridge that needs safety monitoring is a prime candidate for cost-effective fiber optic sensor monitoring, in which the fibers can be embedded or retro-actively attached to the bridge to detect strain and risk of failure before the bridge actually fails. As long as the fiber is not bent excessively, the fiber can be installed in a sine wave shape to allow for more data points across a surface. An OTDR can detect micro and macro bends and can be used to optimize the fiber strain and bends at the installation of the fiber sensor if a slightly strained fiber is required in the application.

Fiber Optic Sensing can provide multiple types of data through optical time domain reflectometry (OTDR) including data on the acoustics, strain, temperature and light transmission properties that indicate movement, or bends and breaks in the fiber. This data can be provided across the entire length of the fiber(s) instead of being limited to discrete and intermittently placed sensor sites. For example, using an OTDR to measure these items will reveal where the temperature changes by gradient across a long fiber span. One can also see where strain in the form of fiber elongation begins and ends. In telecommunications, strain needs to be avoided and thus measuring this protects the network and allows proactive cable strain mitigation and repair. If one wants to monitor a bridge, the strain on the fiber sensor can indicate movement of the bridge such as sagging, sinking or stress caused by separation of the bridge plates.

Consider measuring temperature throughout a building that requires a very specific temperature range, such as a data center, nuclear plant, or blood bank storage facility. Traditional electrified thermostatic sensors are placed in several locations and take periodic discrete point readings. Electronic temperature sensors are expensive and requires constant electrification. What happens when the location is missing a sensor or the sensor fails due to power loss, temperature extremes, or EMI interference? The temperature is not optimally regulated creating a hot or a cold spot. A fiber optic sensor net in the form of one or more fiber cables can be run throughout the building to obtain readings across continuous locations. The fiber net can provide more data points for better coverage at a lower cost with higher reliability. A pulse of light emitted by a laser OTDR is all that is required to interrogate the fiber sensor and the device can be powered by a battery in case of a power outage for more than a day.

In addition, Distributed Acoustic Sensing (DAS) provides information about sound frequencies and vibrations along a sensing fiber providing continuous and dynamic real-time information of vibrational disturbances occurring in the environment around your assets. This enhances threat detection capability, enabling detection and localization of specific external threats swiftly, from security perimeter breaches to unplanned construction works (e.g. manual or mechanical digging) to environmental hazards or events. It provides the critical intelligence to identify and pinpoint threats which is required to react promptly and to protect your assets.

What are some game-changing applications of fiber optic sensors?

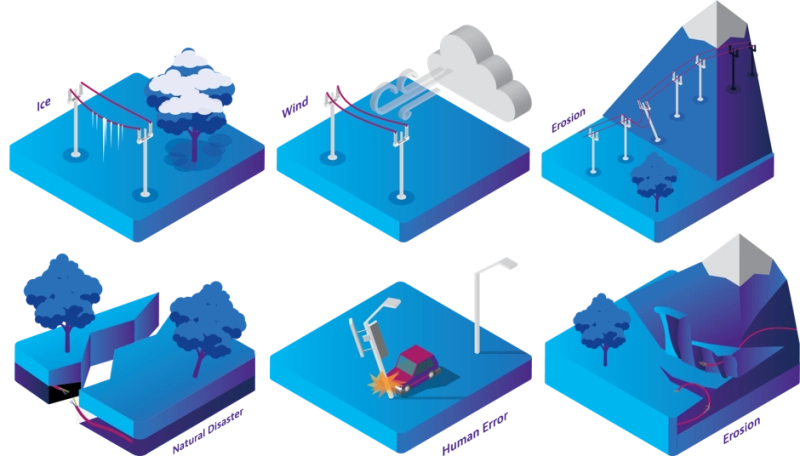

Communications cables are placed all over the world in rugged, inhospitable subterranean, submarine and aerial environments where ice, wind, earth movement/erosion, waves, vandalism, and human error constantly strain or break the cables, causing both service outages and service degradation. Cables are sometimes strained accidentally during installation. Once excessively strained, the cable is at risk of breaking and the lifespan of the cable is dramatically reduced from 35-40 years to potentially just months.

Long-haul and submarine cables are mission critical but are difficult to service in inclement weather or remote, dangerous terrain. Distributed strain sensing with a fiber optic sensor will allow a network cable owner to test the fiber at installation, and then monitor a dark fiber for excessive strain risk and changes in strain while in service to mitigate breakage. Mauritania recently experienced a break in the submarine cable that disconnected the entire network from the internet for two days. This was caused when a trawler lifted the African Coast to Europe cable off the sea floor and broke it. Had this cable been monitored for strain, an alarm would have triggered as the cable was being pulled before it broke. If it did end up breaking, a classic Rayleigh OTDR could have located the break within one meter, thus reducing the outage time. Long-haul and submarine cables are mission critical but are difficult to service in inclement weather or remote, dangerous terrain. Distributed strain sensing sensing with a fiber as a sensor will allow a network cable owner to test the fiber at installation, and then monitor a dark fiber for excessive strain risk and changes in strain while in service to mitigate breakage. Distributed acoustic sensing will allow for monitoring to detect approaching threats such as fishing nets or ships anchors. Mauritania recently experienced a break in the submarine cable that disconnected the entire network from the internet for two days. This was caused when a trawler lifted the African Coast to Europe cable off the sea floor and broke it. Had this cable been monitored for strain or acoustics, an alarm would have been triggered as the cable was being approached and as being pulled before it broke. If it did end up breaking, a classic Rayleigh OTDR could have located the break within one meter, thus reducing the outage time.

Consider an aerial cable bearing an excessive ice load. The network operator can monitor the cables and locate network segments where staff should perform ice removal to prevent excessive strain. After a strain event has occurred, the cable can be tested against MAT tolerance measurements to be prioritized for replacement. Both portable DTSS fiber optic sensor OTDRs and rack-mounted fiber interrogation OTDRs are available.

The most common cause of cable breakage is due to construction digging, aka backhoe attenuation. Often when the break is located, the cable is spliced or connectorized at the break location. However, this may only resolve the problem temporarily because the strain has damaged many meters of cable on both sides of the break when the backhoe pulled the cable out of the ground.

The cable may break again as it is re-installed or become so degraded that it is too damaged to provide adequate service. Repeat repairs are expensive and cause additional service outages. By taking distributed strain measurements with a fiber optic sensor OTDR in both directions up and down the cable when the break occurs, the technician can provide scientific evidence to demonstrate precisely which section(s) of cable should be replaced. This evidence can be used to charge the responsible party for the cost of the damage. It prevents further repeat repair dispatches and service disruption to customers as well as unnecessary repairs on good cable sections that have not experienced strain damage.

Pipelines carry all types of expensive and potentially caustic materials in the oil, chemical, food, waste and water industries. A spill, leak that causes contamination into the pipeline, or theft can cause catastrophic problems. Pipeline monitoring is accomplished by measuring fibers for temperature and strain along the pipeline. Likewise, a dam or dike can be monitored similarly. A leak is suspected if there is a dramatic change in temperature, or the strain or light reflectance properties of the fiber. Temperature can be indicative of a leak or tap, strain is indicative of risk of breakage due to unexpected movement, and the problem can be located within a meter by using classic light reflectance Rayleigh scattering OTDR analysis. A combination optical interrogator, for strain, temperature and light reflectance can be used in a rack-mounted OTDR monitoring solution to continually monitor the fiber sensors attached to the pipeline. Fiber optic sensors provide accurate detection allowing shutdown, inspection, and repairs to be done quickly.

Electrical hot spots on power transmission plants cause life-threatening fire risk and infrastructure damage. A recent example may have happened in California, USA when an electrical hot spot or downed electric cable may have ignited a forest fire. Lives and property were lost and now the utility is facing lawsuits and bankruptcy.

Remote fiber sensing using distributed temperature sensing (DTS) is the only economical way to monitor such problems and is much less expensive than the cost of such a catastrophic event. A fiber is placed along the transmission line to remotely monitor the line. An alarm is triggered when the fiber optic sensor system detects a rise in temperature, a strain or bend that can indicate a line fall. By pairing it with Rayleigh OTDR analysis, a precise location can be determined when there is either a gradual or abrupt shift in the fiber position by comparing a reference trace to a constant, periodic trace. The alarm can trigger an emergency power shutdown and investigation of the transmission lines. Because the fiber analysis using a fiber optic sensor is immune to EMI, it is the ideal source of data in this high EMI environment.

Support at Every Step

We provide support, services, comprehensive training and the resources you need. It’s all part of what we do to maximize the value of your VIAVI investment.

Ask an Expert

Contact us for more information or to receive a price quote. We have the experts to give you the right answer on any of your questions.