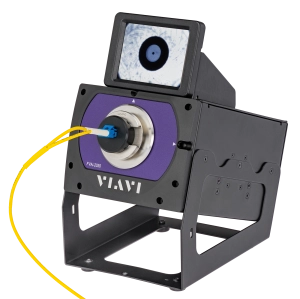

The new FVA digital fiber microscope is a unique device that fully automates the inspection process, significantly reducing inspection time and simplifying workflow. The FVA microscope is used to inspect the polished surface of fiber optic connectors, and its high-resolution results are ideally suited for post-polish inspection of high quality end faces. It also detects scratches that technicians may miss, delivering the level of sensitivity long sought in the industry. The FVA is powered by a 12V adapter (included) and a PC via USB 2.0.

FiberChekPRO is an advanced application that determines the acceptability of optical fiber end faces through automated inspection and analysis. It identifies and characterizes defects and contamination and determines their location relative to the fiber core. It then provides a PASS or FAIL result according to a pre-configured failure criteria setting.

Highlights

- Eliminate subjectivity from inspection with a fully automated repeatable system for fiber inspection

- Significantly reduce total inspection time by removing the need to focus the fiber manually

- Document that your product is compliant to end face quality standards, such as IEC-61300-3-35

- Easily define and enforce your Pass/Fail criteria

Applications

- Automatically inspects and analyzes fiber optic connectors in manufacturing and quality assurance environments

- Automatically focuses, centers, captures, and analyzes fiber end face images, and obtains instant Pass/Fail result

- Standardizes fiber inspection and analysis procedures

Key Features

- Fully-automated inspection system:

- Quickly and consistently focuses and centers fiber end face

- Locates and counts defects and scratches

- Evaluates against Pass/Fail criteria

- Adjustable, scalable automation settings from all-manual to all-automated

- Archives results and images in HTML or PDF formats and generates integrated reports

- Plugs directly into PC via USB 2.0 connection

- FiberChekPRO pre-programmed with International Electrotechnical Commission (IEC) acceptance criteria standards for single-mode and multimode connectors

Software Download

Software & Firmware Releases

Software Download

White Papers & Books

-

VIAVI Care Support

Services Bronze Silver MaxCare Image Image

Image Image

Image

Technical Assistance Premium Premium Premium Factory Repair Priority Service Self-paced Training Factory Calibration Express Loaner * 5-year plans only; if applicable

-

VIAVI Care Support for Existing Equipment

FleetCare plans can be customized to include any service entitlements on your fleet of existing equipment. Please fill out a Service Contracts form for a quote.

- Any collection instruments with a single coterminous renewal date

- Each contract is customized with any number of annual terms required by the customer

- Onsite Calibration, Training, Field Application Engineer days can be added

-

Repair and Calibration

Our products live in rugged environments for more than 10 years with 1000s of test connect/disconnect cycles. We will be there to support you to ensure components that require maintenance like connectors, batteries, and software updates are ready to test accurately for years to come. We apply factory procedures fast, automated calibration and functional verification, maintenance using OEM parts, and the application of all engineering change orders and software updates. Services are available through contract Care plans, FleetCare or per incident as requested.

Top 4 Reasons to Choose VIAVI for Your Repair and Calibration Needs:

- Minimize business disruption

- Budget

- Measurement Accuracy and Product Reliability

- Measurement Compliance, TL9000 certification and OEM Standards

Support at Every Step

We provide support, services, comprehensive training and the resources you need. It’s all part of what we do to maximize the value of your VIAVI investment.

Let Us Help

We’re here to help you get ahead.