Fiber Test

Fiber optic test tools from VIAVI will help you effectively install, maintain, and test your fiber optic networks while ensuring optimal performance

Fiber testing involves a range of procedures, tools, and benchmarks employed to assess fiber optic components, links, and networks in operation. It encompasses both optical and mechanical evaluations of individual elements, as well as thorough transmission tests conducted to ensure the reliability and effectiveness of entire fiber network setups.

Essential Fiber Optic Testers

-

INX 700 Probe Microscope

Automated single and multifiber connector inspection and the industry’s first AI-enhanced image analysis

-

INX 660 Probe Microscope

Automated single fiber connector inspection and analysis

-

OneExpert HFC (ONX 720/730)

Comprehensive DOCSIS, PON, Ethernet, and WiFi 7 testing made easy through integrated automation.

-

OneExpert Fiber (ONX-700)

Comprehensive PON, Ethernet, and WiFi 7 testing made easy.

-

FI-60 Live Fiber Identifier

Live Fiber Identifier easily identifies the optical signal without having to disconnect the fiber or disrupt network...

-

Visual Fault Locators

Visual fault locators for fiber bends and breaks, localization of damages and end-to-end continuity check.

-

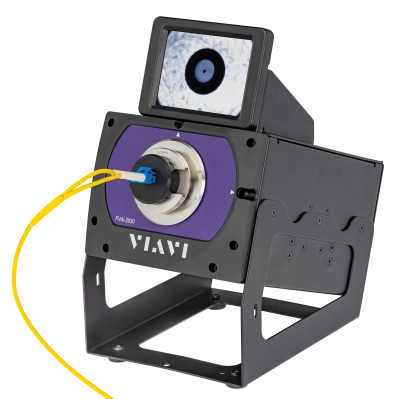

P5000i Fiber Microscope

Automated Fiber Inspection & Analysis Probe provides PASS/FAIL capability to PC, laptops, mobile devices and...

-

FiberChek Probe Microscope

The "all-in-one" handheld solution for fiber inspection.

-

MP-60/-80 Miniature USB 2.0 Power Meters

Measures optical power via a USB 2.0 connection to a PC/laptop/smart device - makes digital processing of optical...

-

SmartPocket V2 OLP-35V2/-35SC/-38V2 Broadband Power Meters

A family of pocket-sized and low-cost optical power meters for the installation and maintenance of single mode and...

-

SmartClass Fiber OLP-82/-82P Inspection-Ready Optical Power Meters

Designed for the installation and maintenance of single mode and multimode fiber optic networks. Combine pass/fail...

-

SmartClass Fiber OLP-85/-85P Inspection-Ready Optical Power Meters

With a 100 dB dynamic range, the OLP-85 and -85P are perfect for any fiber-optic network power or loss test...

-

SmartPocket V2 OLS Optical Light Sources

A family of pocket-sized and low-cost optical light sources for the installation and maintenance of single mode and...

-

SmartClass Fiber OLS-85 Inspection-Ready Optical Light Sources

The OLS-85 inspection-ready optical light source is the ideal partner to the SmartClass Fiber OLP-85 and OLP-85P to...

-

SmartPocket V2 OMK-35V2/-36V2/-38V2 Optical Test Kits

A family of pocket-sized and low-cost optical power meter plus optical light source kits for the installation and...

-

SmartClass Fiber ORL-85 Inspection-Ready Optical Return Loss Meters

The SmartClass Fiber ORL-85 combines optical power meter (OPM), light source (OLS), continuous wave return loss...

-

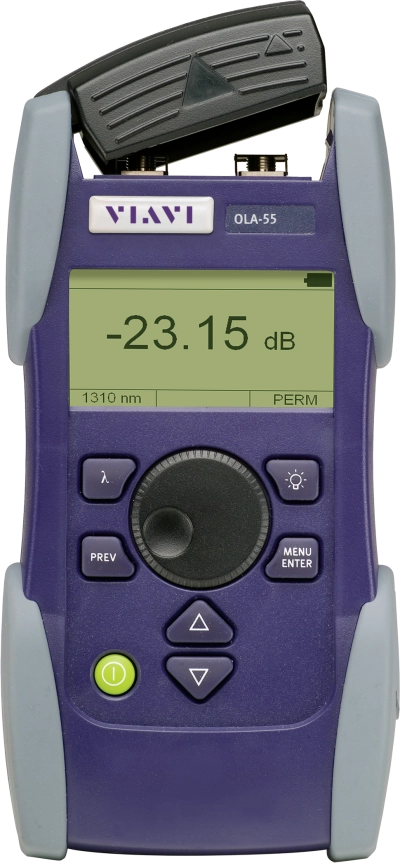

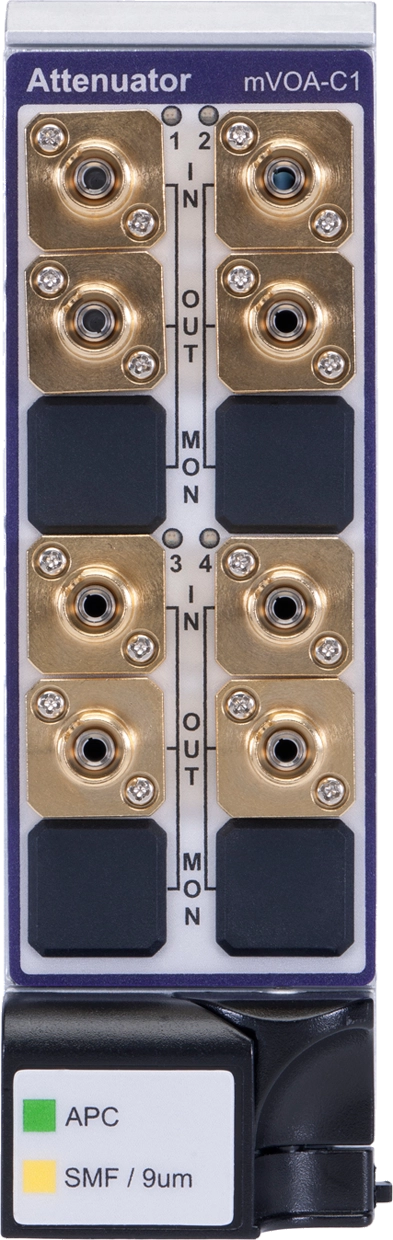

SmartClass OLA-54/-55/-55M Optical Level Attenuators

Compact and rugged handheld attenuators for field or lab use.

Fiber Characterization

-

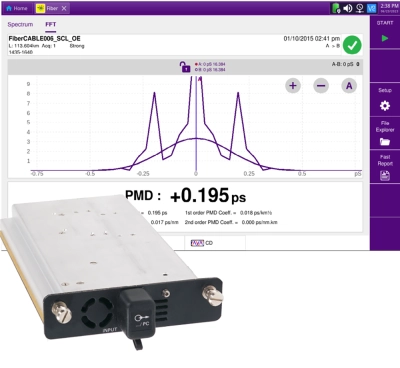

Optical Dispersion Measurement (ODM) Modules (8100 Series)

Integrated fiber characterization and dispersion test solution combining PMD, CD, and AP measurements to...

-

Optical Broadband Light Sources

Optical broadband light source for characterization and dispersion testing (PMD, CD, and AP) of high speed networks...

-

FiberTrace 2 and FiberCable 2 Reporting Software

Post-processing and reporting PC software to view, edit, analyze and generate accurate and updated documentation of...

-

FiberComplete PRO

Bidirectional IL/ORL and OTDR fiber acceptance testing done with just one fiber connection and a single button press...

-

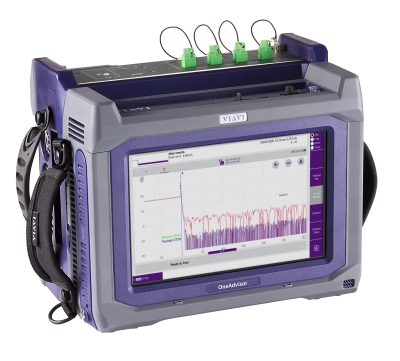

OneAdvisor 800 Fiber Platform

Fiber Optic Network Installation, Turn-Up, and Troubleshooting Platform

-

OTDR Modules (4100 Series)

OTDR test solution for use in installing, turning up, and maintaining long-haul, metro, FTTx/PON, access, and...

Fiber Inspection and Cleaning

-

INX 700 Probe Microscope

Automated single and multifiber connector inspection and the industry’s first AI-enhanced image analysis

-

INX 660 Probe Microscope

Automated single fiber connector inspection and analysis

-

FiberChek Probe Microscope

The "all-in-one" handheld solution for fiber inspection.

-

P5000i Fiber Microscope

Automated Fiber Inspection & Analysis Probe provides PASS/FAIL capability to PC, laptops, mobile devices and...

-

FV Benchtop Microscopes

Microscopes that equip optical connectivity manufacturers with the ability to ensure clean fiber connector end-faces...

-

FVAM Series Benchtop Microscopes

"All-in-one" benchtop inspection and analysis solution for multifiber connectors such as MPO and pluggable...

Fiber Optic Light Sources

-

SmartPocket V2 OLS Optical Light Sources

A family of pocket-sized and low-cost optical light sources for the installation and maintenance of single mode and...

-

SmartPocket V2 OMK-35V2/-36V2/-38V2 Optical Test Kits

A family of pocket-sized and low-cost optical power meter plus optical light source kits for the installation and...

-

SmartClass Fiber OLS-85 Inspection-Ready Optical Light Sources

The OLS-85 inspection-ready optical light source is the ideal partner to the SmartClass Fiber OLP-85 and OLP-85P to...

-

SmartClass Fiber ORL-85 Inspection-Ready Optical Return Loss Meters

The SmartClass Fiber ORL-85 combines optical power meter (OPM), light source (OLS), continuous wave return loss...

Fiber Optic Sensing

-

FTH-DAS

Protect critical infrastructure from external threats and monitor pipelines for leaks with the most versatile...

-

FTH-DTSS

Monitor temperature and strain of power cables, pipelines and telecom cables with the most versatile optical fiber...

-

FTH-DTS

Monitor temperature of power cables, pipelines and telecom cables with the most versatile optical fiber sensing...

-

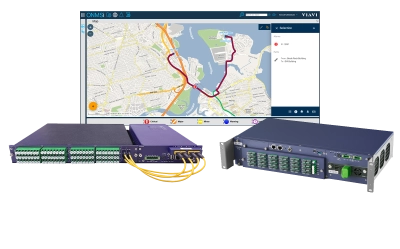

ONMSi Remote Fiber Test System (RFTS)

ONMSi Optical Network Management System for Core, Metro, Access and FTTH networks.

-

OneAdvisor 800 DTS

Bring distributed temperature sensing technology to the field in a uniquely portable solution. Audit, check and...

-

OneAdvisor 1000 DTSS

Bring distributed temperature and strain sensing technology to the field in a uniquely portable solution. Audit,...

MPO Testing

-

INX 700 Probe Microscope

Automated single and multifiber connector inspection and the industry’s first AI-enhanced image analysis

-

SmartClass Fiber MPOLx - MPO Optical Loss Test Sets

The VIAVI Solutions SmartClass Fiber MPOLx is the industry’s first dedicated optical loss test set that can perform...

-

FiberComplete PRO

Bidirectional IL/ORL and OTDR fiber acceptance testing done with just one fiber connection and a single button press...

-

Data Center Expert 700 (DCX 700)

Tier 1 Multifiber Optical Loss Test Set

-

Multi-fiber MPO based Switches for Field Instruments

High capacity switch solutions (12 to 192 ports) to ease and automate high fiber count cable certification: OTDR,...

-

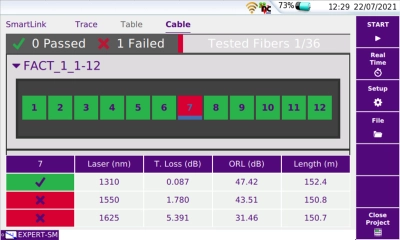

Smart Link Mapper (SLM) Applications for OTDR Testing

Icon-based map view of OTDR events and instant pass/fail display for easy OTDR results interpretation and analysis...

Optical Power Meters

-

SmartPocket V2 OMK-35V2/-36V2/-38V2 Optical Test Kits

A family of pocket-sized and low-cost optical power meter plus optical light source kits for the installation and...

-

SmartPocket V2 OLP-35V2/-35SC/-38V2 Broadband Power Meters

A family of pocket-sized and low-cost optical power meters for the installation and maintenance of single mode and...

-

SmartPocket V2 OLP-37XV2 Selective PON Power Meter

Wavelength selective optical power meter for use in G/E-PON and XGS-PON/10G-EPON and hybrid systems.

-

SmartPocket V2 OLP-39 TruePON Testers

TruePON Testers for use in G-PON, XGS-PON and hybrid systems.

-

OneExpert HFC (ONX 720/730)

Comprehensive DOCSIS, PON, Ethernet, and WiFi 7 testing made easy through integrated automation.

-

MP-60/-80 Miniature USB 2.0 Power Meters

Measures optical power via a USB 2.0 connection to a PC/laptop/smart device - makes digital processing of optical...

-

SmartClass Fiber OLTS-85/-85P Optical Loss Test Sets

OLTS from VIAVI: The fastest and easiest solutions for Tier 1 fiber certification

-

SmartClass Fiber MPOLx - MPO Optical Loss Test Sets

The VIAVI Solutions SmartClass Fiber MPOLx is the industry’s first dedicated optical loss test set that can perform...

-

SmartClass Fiber OLP-82/-82P Inspection-Ready Optical Power Meters

Designed for the installation and maintenance of single mode and multimode fiber optic networks. Combine pass/fail...

-

SmartClass Fiber OLP-85/-85P Inspection-Ready Optical Power Meters

With a 100 dB dynamic range, the OLP-85 and -85P are perfect for any fiber-optic network power or loss test...

-

SmartClass Fiber ORL-85 Inspection-Ready Optical Return Loss Meters

The SmartClass Fiber ORL-85 combines optical power meter (OPM), light source (OLS), continuous wave return loss...

-

SmartClass Fiber OLP-87 PON Power Meter

The OLP-87 PON Power Meter enables simultaneous power measurement of all upstream & downstream wavelengths on...

-

MAP Optical Power Meter (mOPM)

InGaAs and Si Optical Power meter for MAP Series

-

OneExpert HFC (ONX 720/730)

Comprehensive DOCSIS, PON, Ethernet, and WiFi 7 testing made easy through integrated automation.

-

OneExpert Fiber (ONX-700)

Comprehensive PON, Ethernet, and WiFi 7 testing made easy.

Optical Spectrum Analyzers (OSA)

-

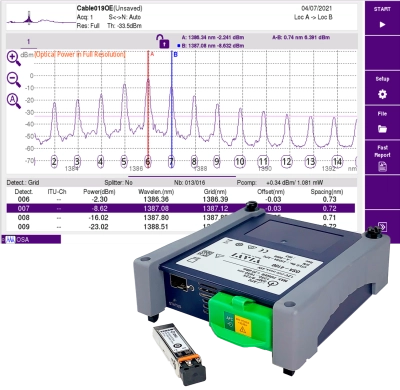

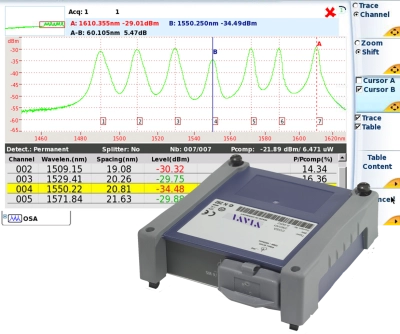

Nano OSA Module (4100 Series)

Compact Nano OSA™ modules offering high resolution measurement over full wavelength band for channel verification...

-

CWDM Optical Spectrum Analyzer Module (COSA-4055)

The COSA-4055 module offers the functionality and speed of an OSA in a handheld form factor at a fraction of the...

-

DWDM Optical Channel Checker Module (OCC-4056C)

The OCC-4056C module offers the functionality and speed of an OSA in a handheld form factor at a fraction of the...

-

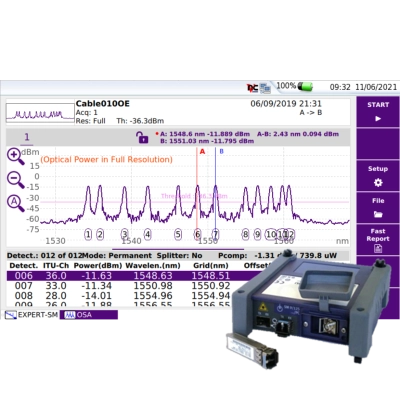

Compact Optical Spectrum Analyzer Module (OSA-110 Series)

Compact full band optical spectrum analyzers for CWDM, DWDM and ROADM systems testing.

-

High Performance Optical Spectrum Analyzer Module (OSA-500 Series)

Full range of optical spectrum analyzers for spectral measurements in CWDM, DWDM, and ROADM testing-based systems,...

-

High Resolution Optical Spectrum Analyzer Module (OSA-610)

High resolution OSA with lab performance in a field-ready tester for spectral analysis of 10/40/100 and 400 G DWDM...

-

Smart Access Anywhere (SAA)

A solution that enables centralized support, on-demand test and live results analysis to support and coach...

-

Optical Spectrum Analyzer Module (mOSA)

Optical grating-based spectrum analyzer with lab-grade spectral performance in a module for the MAP Series

-

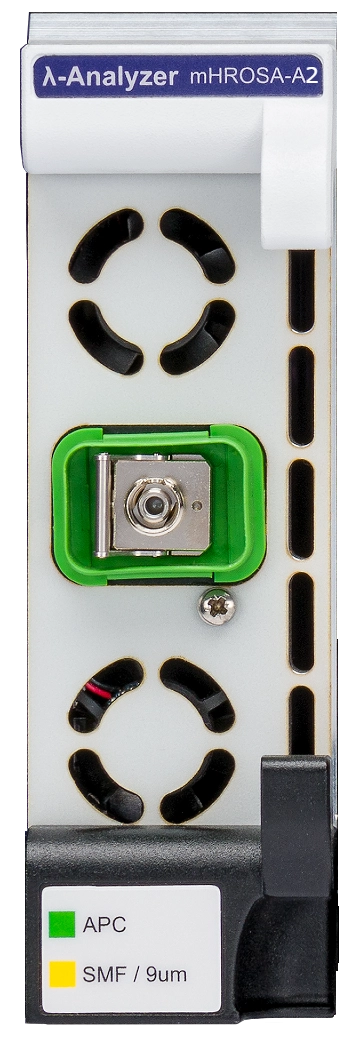

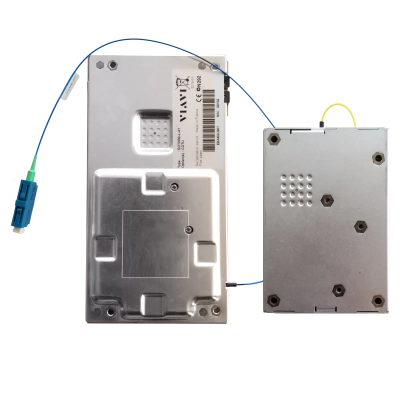

MAP Hi-Resolution Optical Spectrum Analyzer Modules (mHROSA)

The MAP-based integrated multi-wavelength meter and high resolution optical spectrum analyzer module combines sub-...

OTDR Testing

-

SmartOTDR Handheld Fiber Tester

The lightweight and compact SmartOTDR speeds and optimizes field testing of metro and access networks—with a...

-

OTDR Modules (4100 Series)

OTDR test solution for use in installing, turning up, and maintaining long-haul, metro, FTTx/PON, access, and...

-

OTDR Modules (8100 Series)

OTDR test solution for use in the installation, turn-up, and maintenance of Metro, very long-haul and ultra long...

-

FiberComplete PRO

Bidirectional IL/ORL and OTDR fiber acceptance testing done with just one fiber connection and a single button press...

-

Smart Link Mapper (SLM) Applications for OTDR Testing

Icon-based map view of OTDR events and instant pass/fail display for easy OTDR results interpretation and analysis...

-

FiberTrace 2 and FiberCable 2 Reporting Software

Post-processing and reporting PC software to view, edit, analyze and generate accurate and updated documentation of...

-

Multi-fiber MPO based Switches for Field Instruments

High capacity switch solutions (12 to 192 ports) to ease and automate high fiber count cable certification: OTDR,...

-

CWDM OTDR Modules (4100 Series)

A CWDM OTDR test solution to deploy or maintain and troubleshoot in-service CWDM fiber networks

-

DWDM OTDR Modules (4100 Series)

A DWDM OTDR test solution to deploy, maintain and troubleshoot in-service DWDM fiber networks

-

Hi-Res Multimode OTDR Solution

The Hi-Res Multimode OTDR solution has been designed to characterize and locate faults on very short multimode fiber...

-

OneAdvisor 1000 DTSS

Bring distributed temperature and strain sensing technology to the field in a uniquely portable solution. Audit,...

-

Smart Access Anywhere (SAA)

A solution that enables centralized support, on-demand test and live results analysis to support and coach...

Remote Fiber Test and Monitoring

-

ONMSi Remote Fiber Test System (RFTS)

ONMSi Optical Network Management System for Core, Metro, Access and FTTH networks.

-

FTH-5000

Automate optical network monitoring with the most compact rack-mounted, remote OTDR test unit on the market

-

FTH-7000

Adaptive Fiber Test Head FTH-7000 for Remote Fiber Test with OTDR module and Internal Switch Options

-

FTH-9000

Adaptive Fiber Test Head FTH-9000 for Remote Fiber Test with OTDR module and Internal Switch Options

-

iOTDR Cards: Micro and Nano

Integrated OTDR Remote Fiber Testing Solutions (RFTS) for network elements in a small but mighty form factor

-

NITRO Fiber

NITRO Fiber Insight for ONMSi providing customizable data aggregation and analytics dashboards for your fiber...

Be Smarter with Your Fiber Testing

Fiber optic cleaning, inspection, testing and monitoring requires diverse tool sets and capabilities to remain effective in today’s diverse communications technology landscape. Advanced fiber optic tools enable expedient certification, troubleshooting and maintenance while monitoring equipment and cutting edge OTDR devices support the uninterrupted integrity of sensitive fiber optic networks. Collectively, these tools provide the means to deploy and sustain vital fiber optic networks and keep them performing optimally.

Our tools are designed to help you get the job done right, the first time. For every stage of the network lifecycle, VIAVI has the tools to help you get in, get out, and get paid.

Related Resources

Related Links

Support at Every Step

We provide support, services, comprehensive training and the resources you need. It’s all part of what we do to maximize the value of your VIAVI investment.

Ask an Expert

Contact us for more information or to receive a price quote. We have the experts to give you the right answer on any of your questions.